In case one or more elements of our method are machine times, a button will appear on the home screen to access the screen where the elements limited by a machine time of our work standard can be measured.

By clicking on the button, we will access the Machine Times screen.

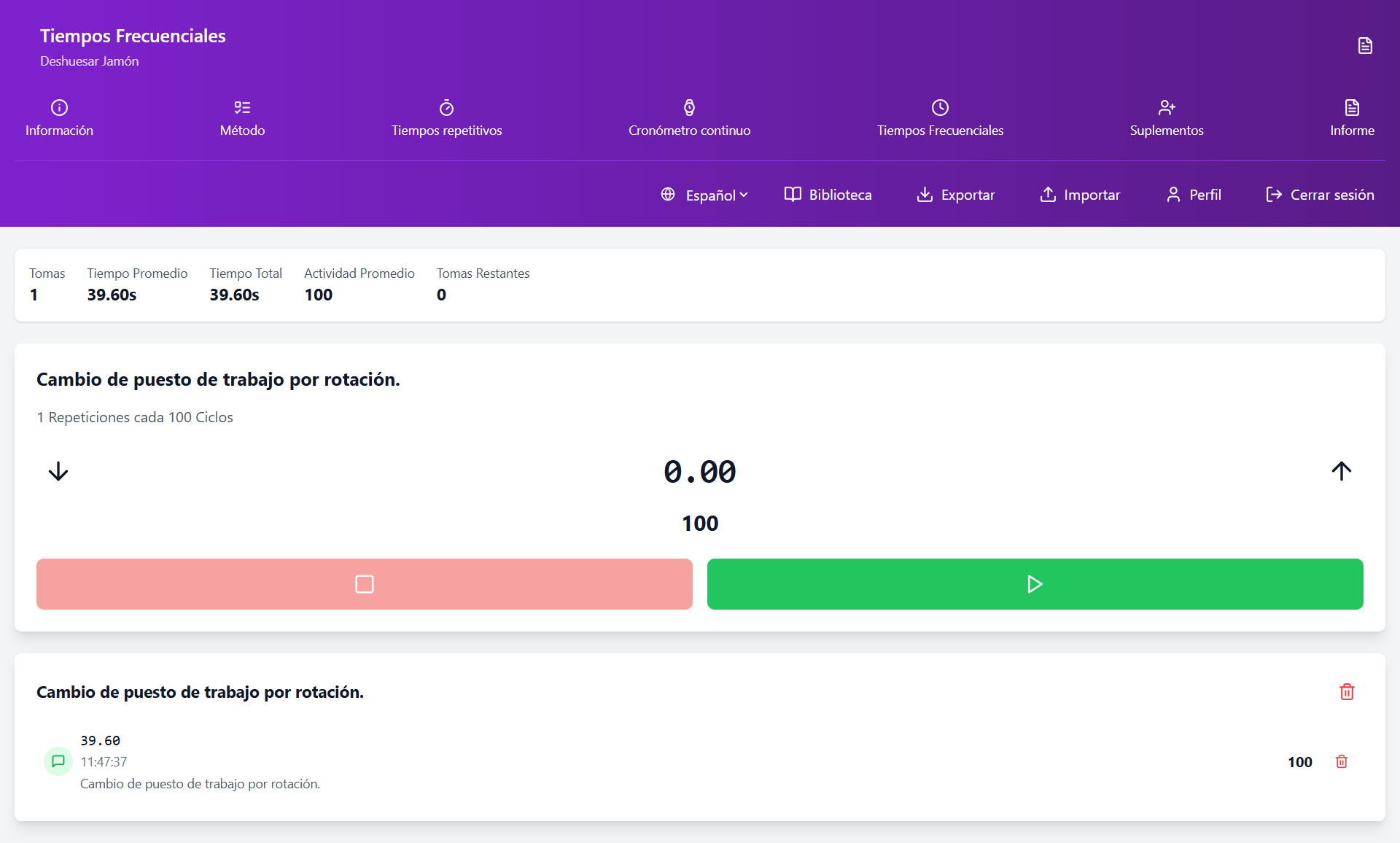

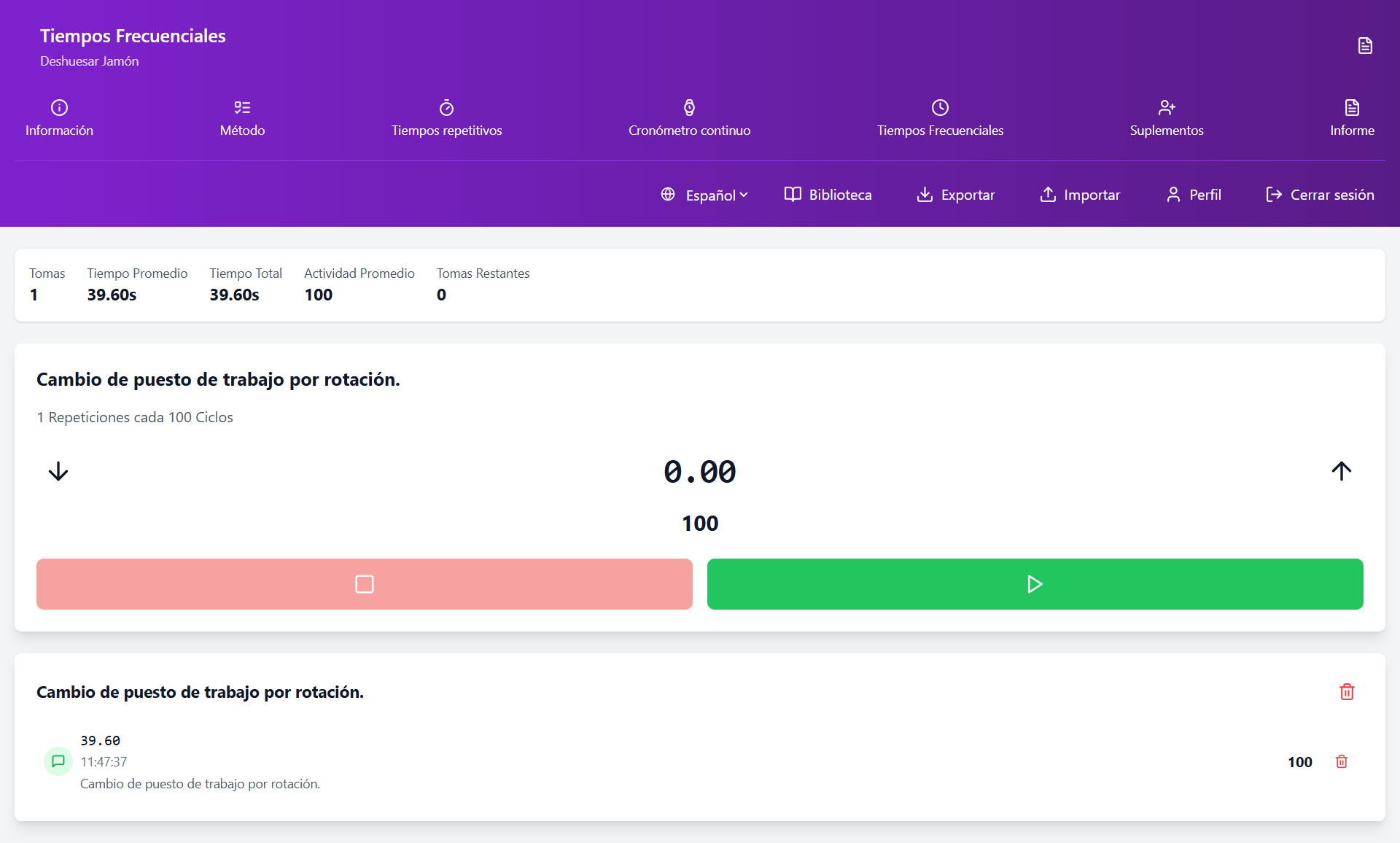

Upon entering, we will see listed all the frequency elements that we have in our method, in this case we only have 1.

If we have already taken a measurement of that frequency element, the AMT (average measured time) will appear. In case we have not taken any measurement or want to take more measurements of that element, we will click on it to access the stopwatch screen.

Record a new measurement

To record a new measurement, we click on the element we want to measure. In our example, we only have 1 machine time and we already have a measurement of it with a value of 4.21 seconds.

To record a new measurement, we click on the play button to start the timing. To stop the timing, we click on the same button. Automatically, it will return us to the initial machine times screen, where we can observe that the average measured time has been modified.

Edit the time of a measurement

In case we need to edit a measurement, we can modify its time by clicking on that measurement. A window will appear where we can enter the new assigned time.

By clicking on the save observed time button, it will direct us to the home screen, where we will see the new AMT (average measured time) for that element of our work standard.

Delete a measurement

Now we have 2 measurements of our machine time element. If we want to delete one of them, we will long-click on the measurement to be deleted.

Upon long-clicking, the measurement will be deleted, recalculating the number of measurements recorded for the element, as well as the average measured time and the total time.

If you want to access the home screen where you will see listed all the elements that are machine time, you can click on the round red button located at the top left.

See questionnaire

Complete lesson

Next lesson

Restart lesson

Conclusion

Mastering industrial time study techniques is essential for any professional seeking to optimize production processes. The systematic application of these methods not only improves operational efficiency but also contributes significantly to cost reduction and increased business competitiveness. Remember that precision in measurement and rigorous analysis of data are the basis for establishing reliable time standards that drive continuous improvement in your organization.