Information Module: Efficient Time Study Management

Configure, customize, and manage your methods and time studies with all the tools needed for professional and precise analysis.

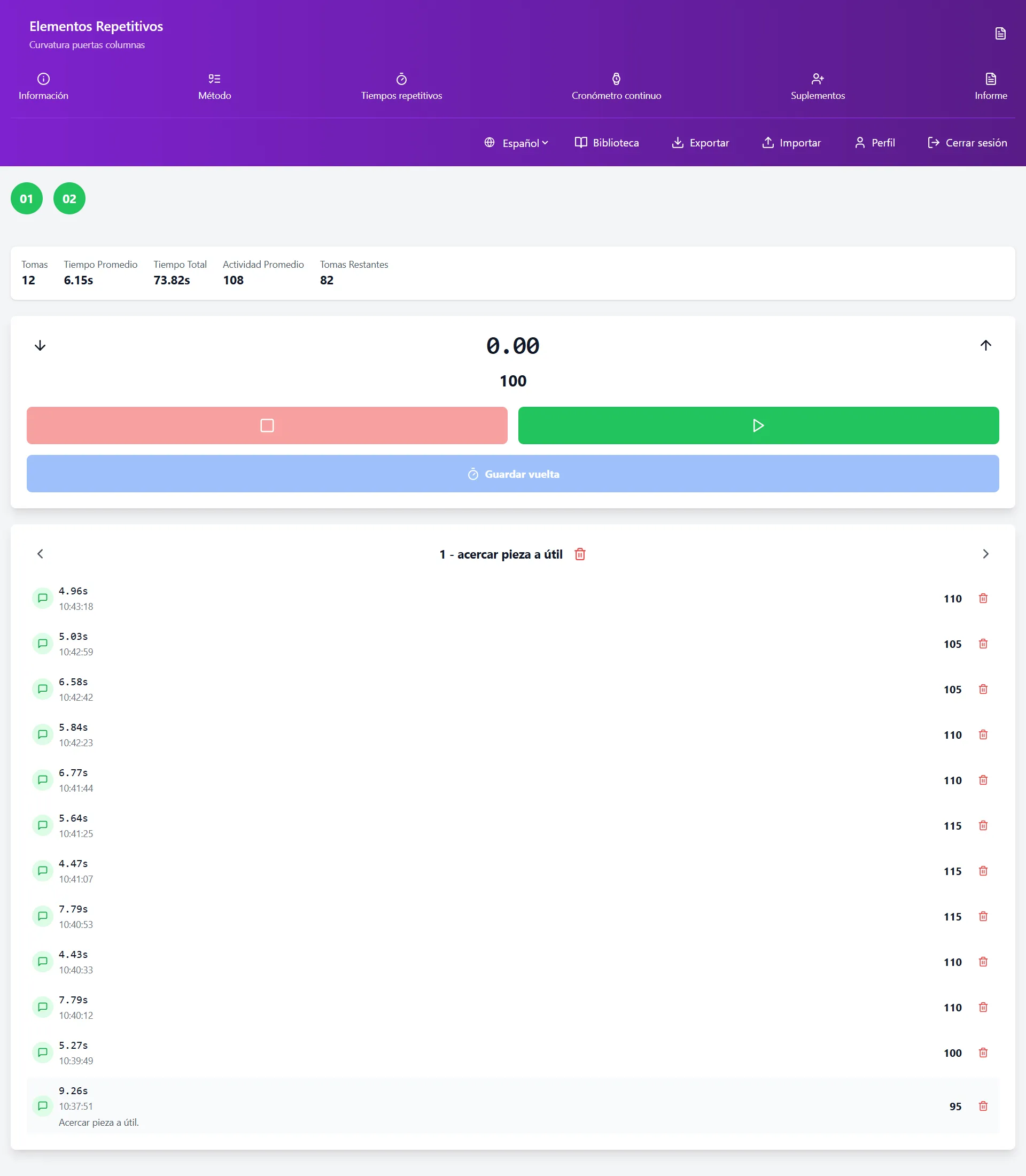

What is the Information Module in CRONOMETRAS?

The Information Module is the core of CRONOMETRAS for configuring and managing methods and time studies. With new features, you can now work with custom units (linear meters, m², m³, kilos, perimeter) and configure advanced parameters for a standard time calculation more precise and professional than ever.

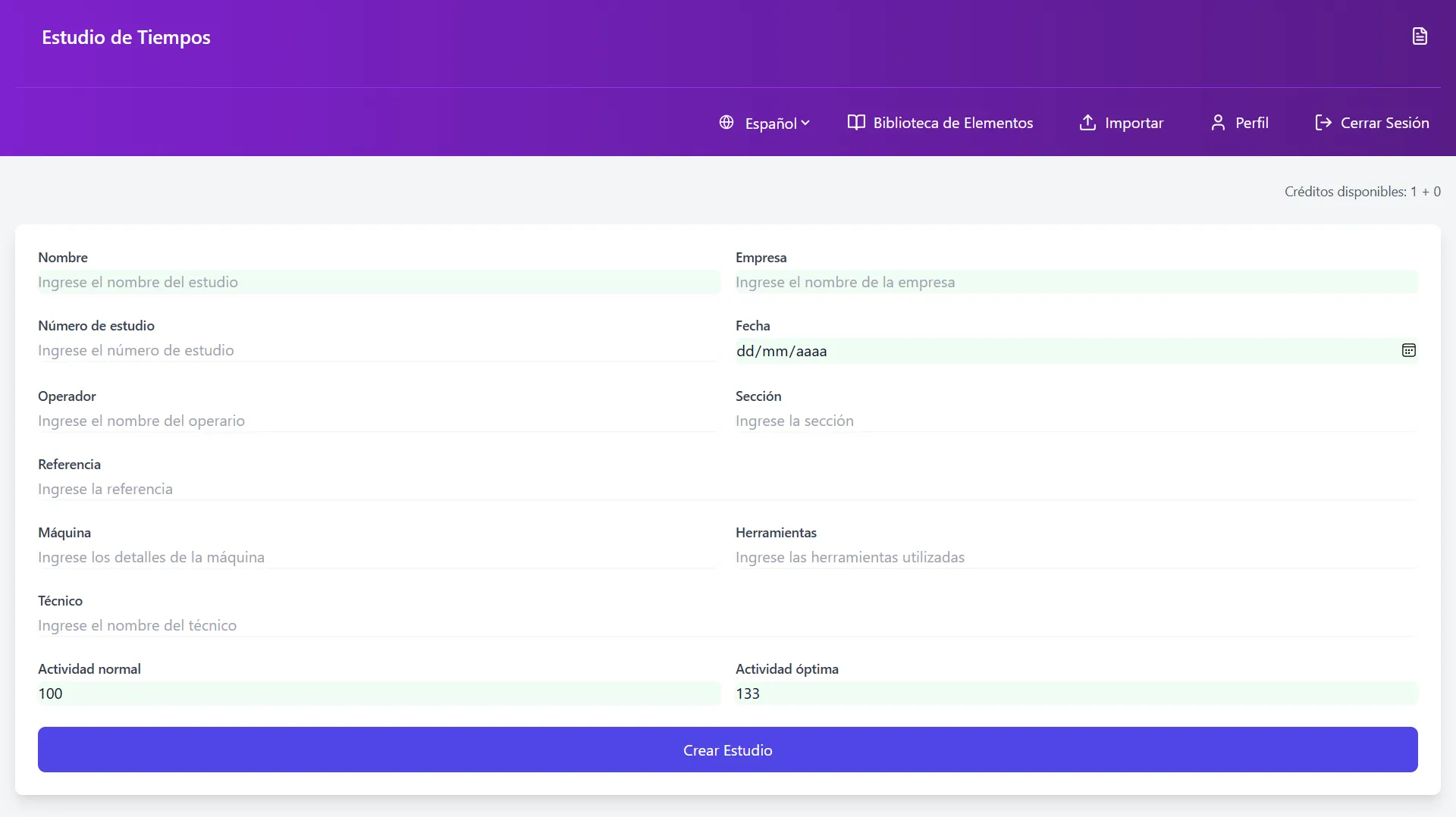

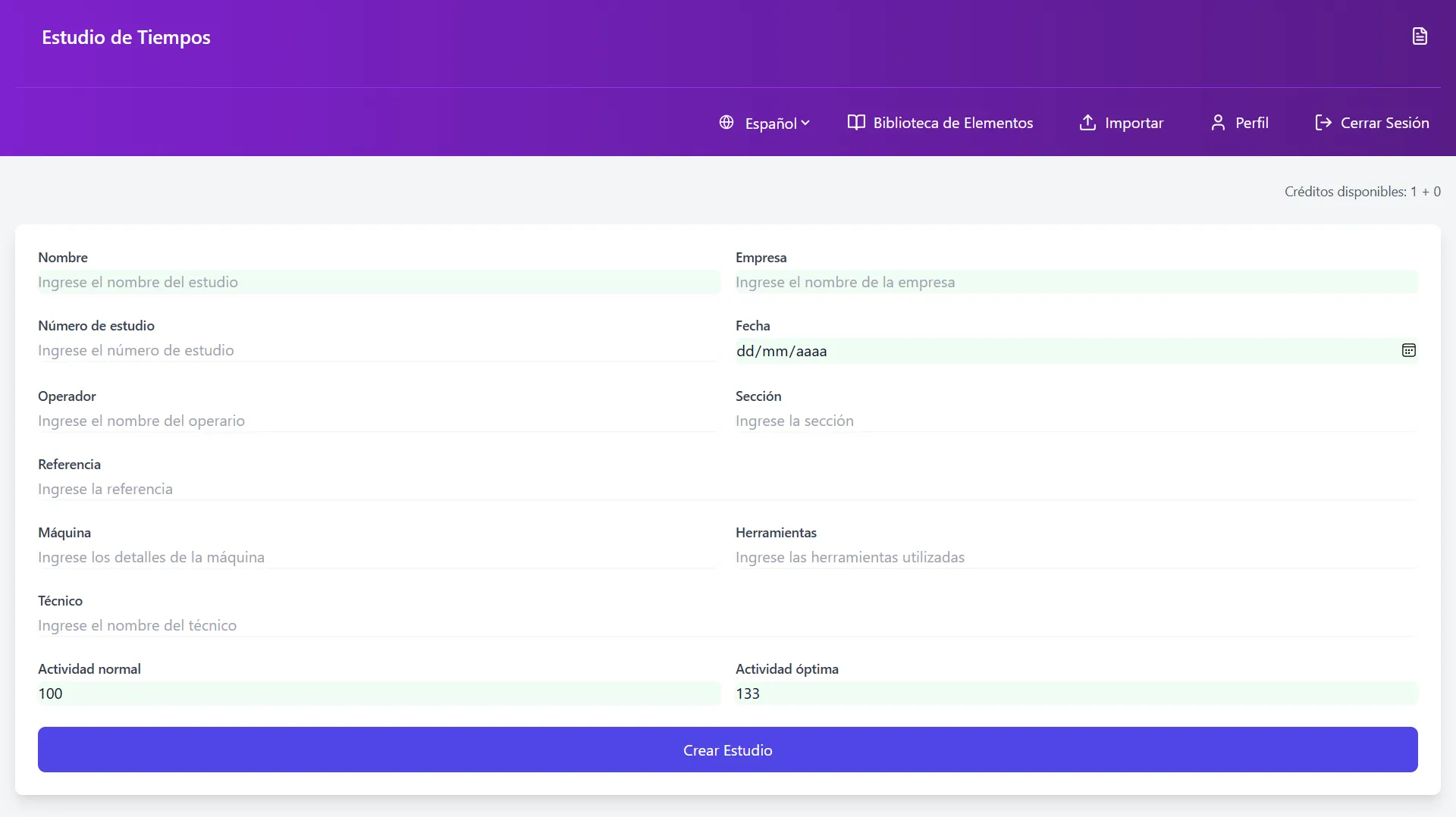

Creation and Editing of Methods and Time Studies: Essential Fields for Industrial Timing

Creating a time and motion study is the fundamental starting point in CRONOMETRAS' industrial timing software. To ensure precise and professional analysis for accurate standard time calculation, the following mandatory fields are required:

- Study Name (name): Unique and descriptive identifier that facilitates the localization and organization of your methods and time studies.

- Company (company): Name of the organization where the study is conducted, essential for classification and comparative analysis across different plants or business units.

- Date (date): Precise temporal record that enables historical tracking of time and productivity evolution over time.

- Activity Scale: Essential parameter for activity assessment in industrial timing:

- Normal: 100 (Default value). Represents the standard work pace according to international work measurement methodologies.

- Optimal: 133 (Default value). Represents the optimal work pace, achievable under ideal conditions, used to set productivity improvement goals.

Optional Fields: Data Enrichment for Comprehensive Time Studies

Professional methods engineering requires detailed documentation. Enrich your time and motion studies with contextual information using the following optional fields that enhance traceability and analysis:

- Study Number (study_number): Internal numerical identifier that facilitates integration with business management systems and systematic study classification.

- Operator (operator): Person performing the studied task, enabling analysis by experience level and tracking skill development over time.

- Section (section): Area or department where the task is performed, essential for line balancing and process optimization by production zones.

- Reference (reference): Reference number or product/process identifier code, facilitating linkage with production planning and quality control systems.

- Machine (machine): Equipment used in the task, critical for human-machine analysis and technical resource optimization.

- Tools (tools): Instruments used during the operation, allowing evaluation of their impact on productivity and workplace ergonomics.

- Technician (technician): Analyst conducting the study, important for traceability and validation of the methodology applied in industrial timing.

- Study Type: Classifies the study based on its nature (production, maintenance, logistics, etc.) for better filtering and organization.

Custom Units: Advanced Measurements for Precise Analysis

CRONOMETRAS' industrial timing software now includes an advanced custom units system that allows for more detailed and precise analysis for various types of work:

-

Square Meters (m²): Ideal for surface-related tasks such as painting, cleaning, or flooring installation.

- Configure length and width for automatic area calculations

- Automatic time calculation per unit of surface area

-

Linear Meters (ml): Perfect for linear tasks such as welding, cutting, or pipe installation.

- Define the total length of the task

- Especially useful for construction and manufacturing tasks

-

Cubic Meters (m³): Essential for volumetric tasks such as earthmoving or container filling.

- Configure length, width, and height

- Automatic calculation of total volume

-

Kilos (kg): For tasks where weight is the determining factor.

- Record the total weight of the material

- Ideal for material handling processes

-

Perimeter: For tasks dependent on the contour of an area.

- Especially useful for fencing or perimeter installation tasks

- Automatic calculation based on provided dimensions

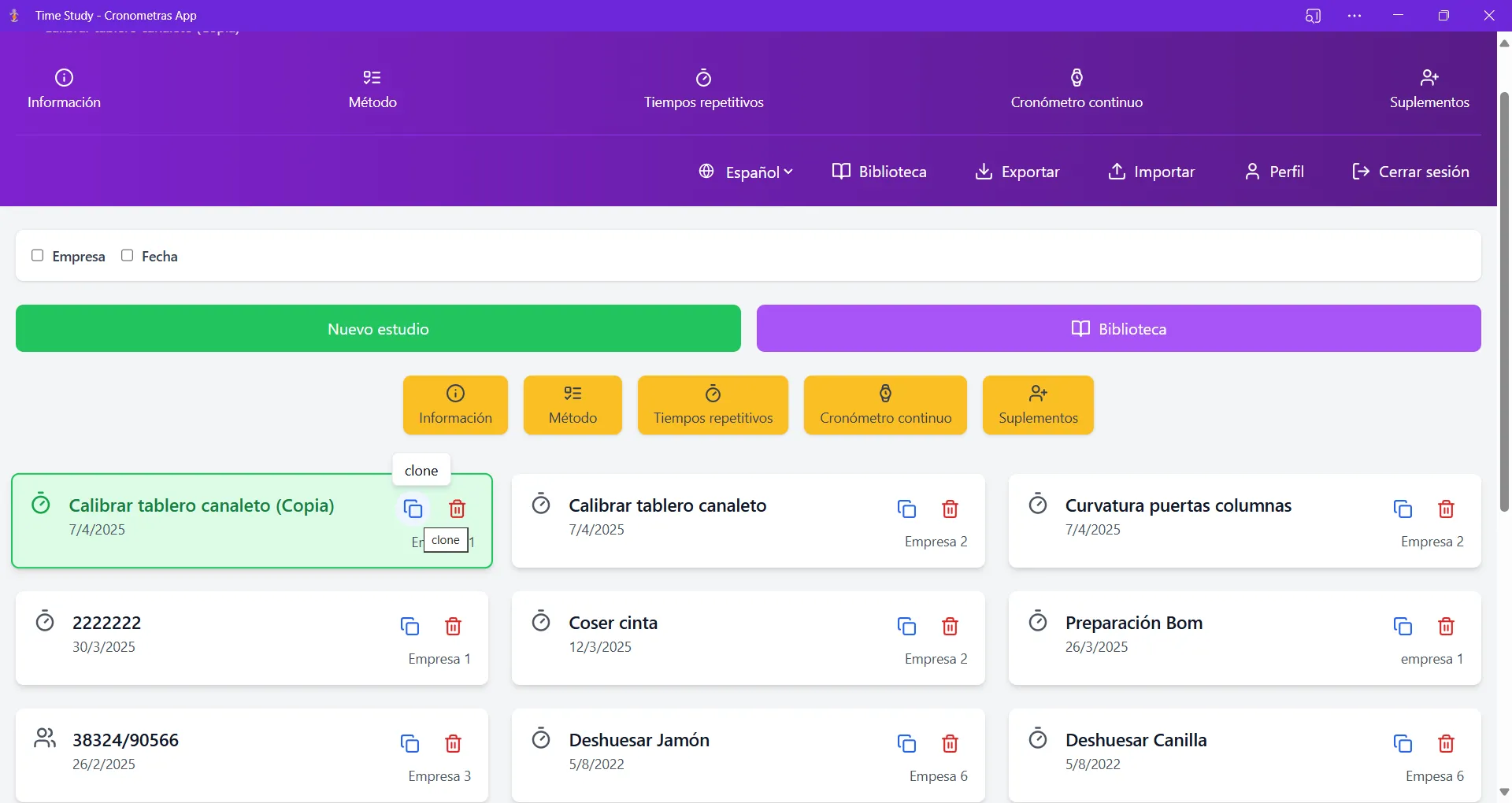

Cloning and Export: Advanced Features for Time Study Management

CRONOMETRAS' industrial timing software offers advanced features that optimize workflow in work measurement and facilitate professional study management:

-

Study Cloning:

- Create an exact copy of an existing study, preserving all element structures and configurations.

- Save significant time by reusing previous studies as a basis for new analyses of similar products or processes.

- Maintain methodological consistency between related studies, essential for work time standardization.

-

Export/Import:

- Export complete studies in standard formats for backups, documentation, or sharing with other departments.

- Import previously exported studies, facilitating collaboration between different plants or external consultants.

- Ensure data portability and continuity of standard time analysis even in offline environments.

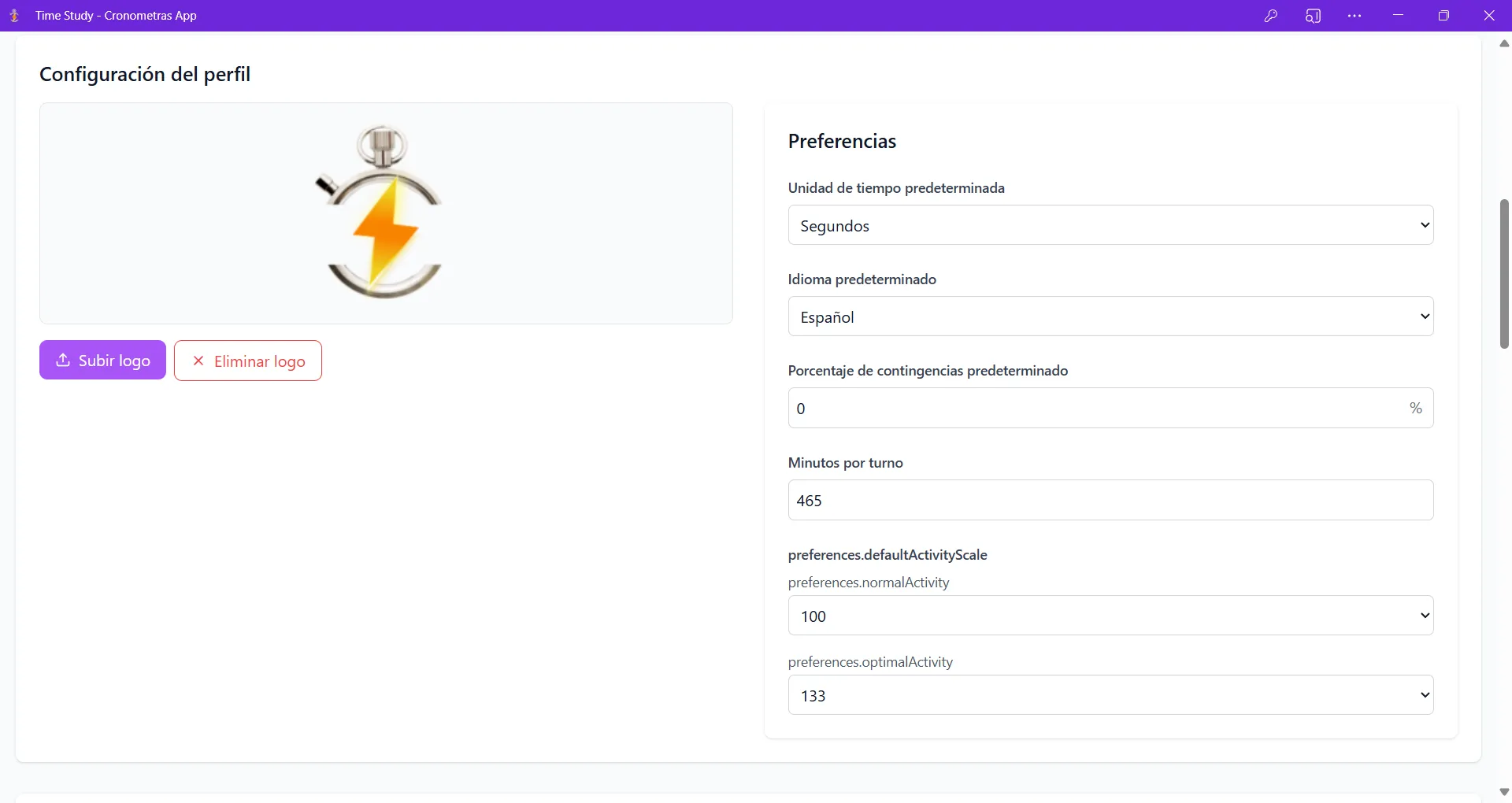

Advanced Configuration: Customization for Professional Time Studies

Modern methods engineering requires flexibility and adaptability. Tailor CRONOMETRAS to your specific needs with advanced options that adapt to various industrial timing methodologies:

Advanced Settings for Professional Time Studies

- Time unit for industrial timing reports:

Configure between minutes, seconds, thousandths of a minute, hundredths of a minute, ten-thousandths of an hour, or TMU (Time Measurement Unit) based on time and motion study standards. Need another specific unit for your industry? Request it

- Effective working minutes per shift:

Set the default available minutes per shift for all your studies, critical for accurate production capacity calculation and human resource planning.

- Contingency percentage for standard time:

Define the default contingency percentage to apply automatically in your studies, following best practices for time standardization in industrial environments.

Data Security and Traceability in Time Studies

- Real-time saving for work measurement:

All changes to your methods engineering studies are automatically saved as you work, ensuring data integrity even in industrial environments with unstable connections.

- Change log for auditing:

The exact creation and last update dates of each study are documented, providing complete traceability for quality certification processes and production standard audits.

Optimize Your Time Study Management with CRONOMETRAS

CRONOMETRAS’ Information Module represents the forefront of industrial timing technology. With new features, our software enables you to take your productivity analysis to the next level:

- Configure and customize all aspects of your time studies according to your industry’s specific needs

- Efficiently manage information from multiple studies with cloning and export tools

- Adapt time units and parameters to international standards or your own criteria

- Ensure the security and traceability of all captured data

- Custom units to adapt to any type of work: linear meters, m², m³, kilos, or perimeter

- Optimize workflow with features designed by methods engineering experts

New!

Custom Units System: You can now configure studies with multiple measurement units (linear meters, m², m³, kilos, perimeter) to perfectly adapt to each project’s specific needs. Create more precise and meaningful reports with just a few clicks.

According to recent studies, companies implementing advanced work measurement systems like CRONOMETRAS achieve up to a 50% reduction in study setup time, improve standard accuracy by 35%, and increase element reuse by 75%, directly translating into significant productivity and profitability improvements.

Industrial Timing Resources

Curso de cronometraje industrial

Curso de cronometraje industrialToma de Tiempos con cronómetro

Ingeniería Industrial

Ingeniería IndustrialLos 5 Métodos de Medición del Trabajo Más Utilizados en la Industria Moderna

Cronometraje Industrial

Cronometraje Industrial7 Errores Comunes al Hacer Cronometraje Industrial (y Cómo Evitarlos con Software)

Eficiencia y productividad

Eficiencia y productividad