Repetitive Times Module: Precision in Measuring Cyclic Operations

Time cyclic operations with precision, obtain statistically reliable results, and optimize your time studies with real-time analysis.

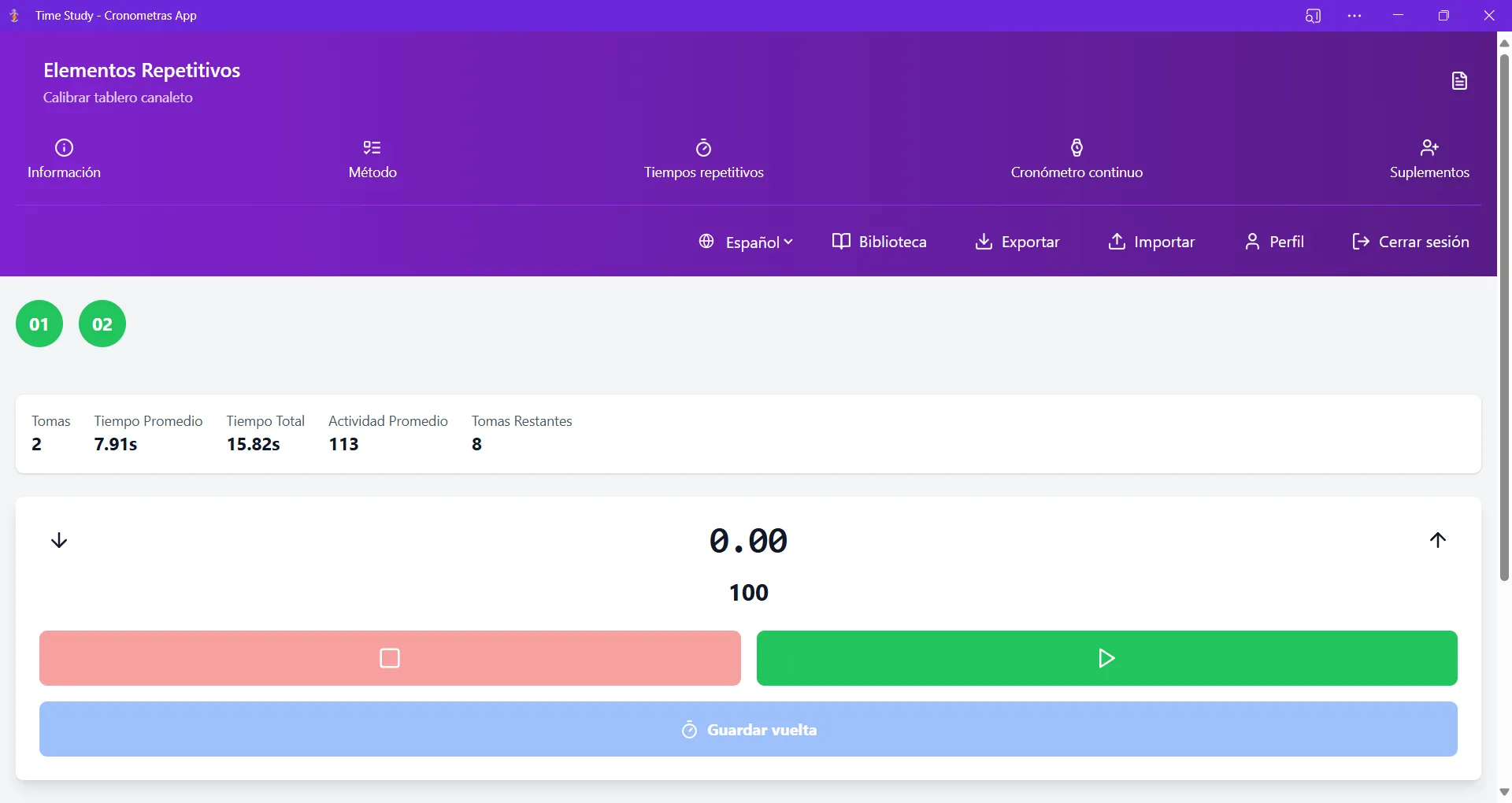

What is the Repetitive Times Module in CRONOMETRAS?

The Repetitive Times Module is a specialized tool in CRONOMETRAS designed to optimize the measurement of cyclic operations in time and motion studies. This module allows industrial analysts to precisely time repetitive elements, manage complete work cycles, and obtain statistically reliable data for standard time calculation, which is fundamental for optimizing production processes.

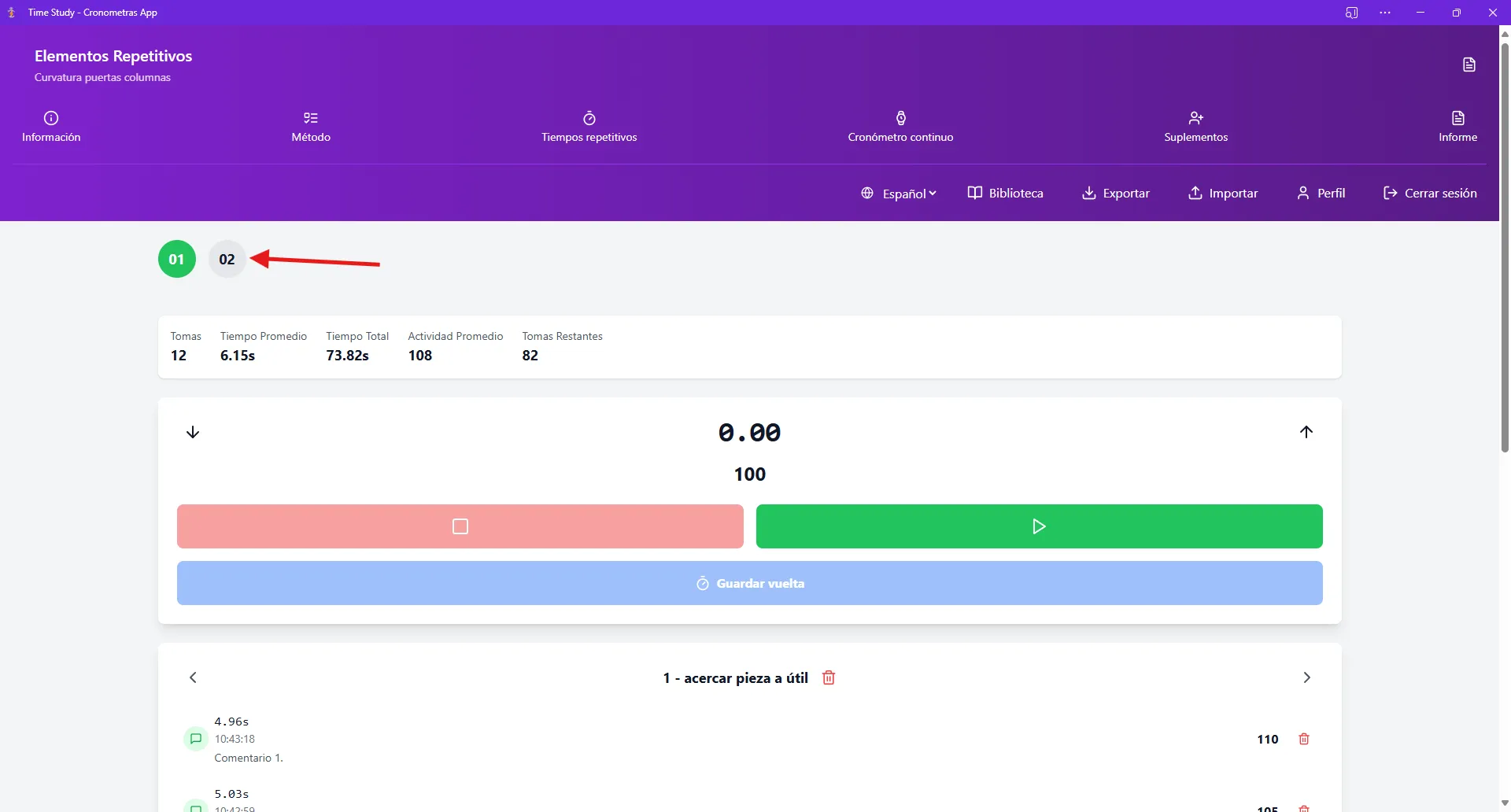

Automated Cyclic Time Study for Accurate Time Studies

The industrial time study software CRONOMETRAS optimizes work measurement in repetitive operations:

• Automatic switch to the next element in the cycle, eliminating sequence errors

• Clear visualization of the current and next element, improving analyst concentration

• Automatic counting of completed cycles for precise progress tracking

• Detailed recording of each repetition for subsequent statistical analysis

Focus your attention on observation and activity rating while CRONOMETRAS handles the sequence, increasing the precision of your time studies.

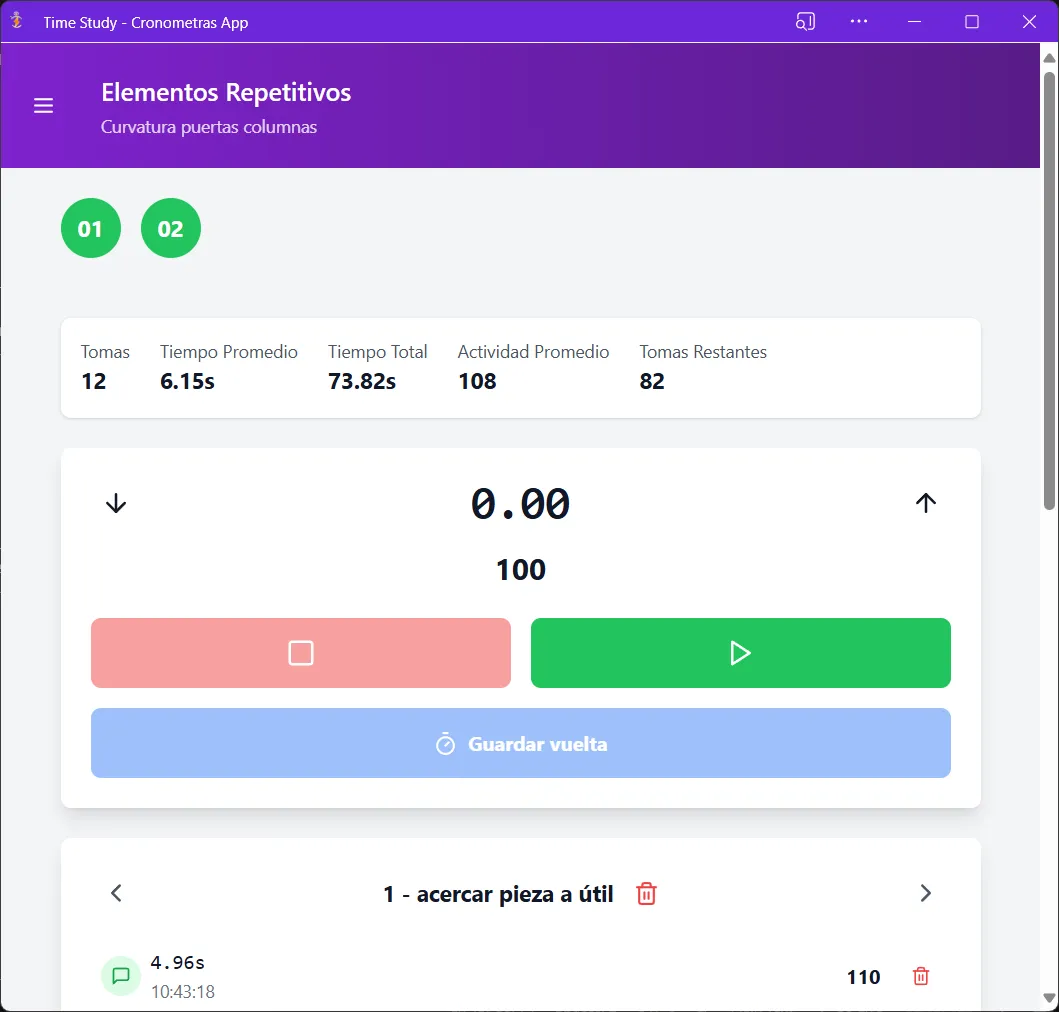

Selective Element Time Study for Flexible Studies

Precise work measurement requires adaptability to different industrial time study situations:

• Temporarily deactivate elements you don't need to measure in a specific cycle

• Select one or more elements to time according to the study's needs

• Record times only for selected elements, optimizing analysis efficiency

• Adapt your stopwatch time study to real plant conditions

Maximize the flexibility of your studies without sacrificing precision or methodological structure.

Real-Time Statistical Analysis for Reliable Time Studies

Accurate standard time calculation requires statistically valid data. CRONOMETRAS provides advanced analysis during work measurement:

• Real-time statistics visualization with automatic update after each cycle

• Automatic variability calculation to identify inconsistencies in the process

• Scientific determination of the number of readings needed according to the required confidence level

• Calculation of average appreciated activity for precise time normalization

• Identification of outlier values that could distort results

Ensure the statistical reliability of your study from the outset, complying with international methods engineering standards.

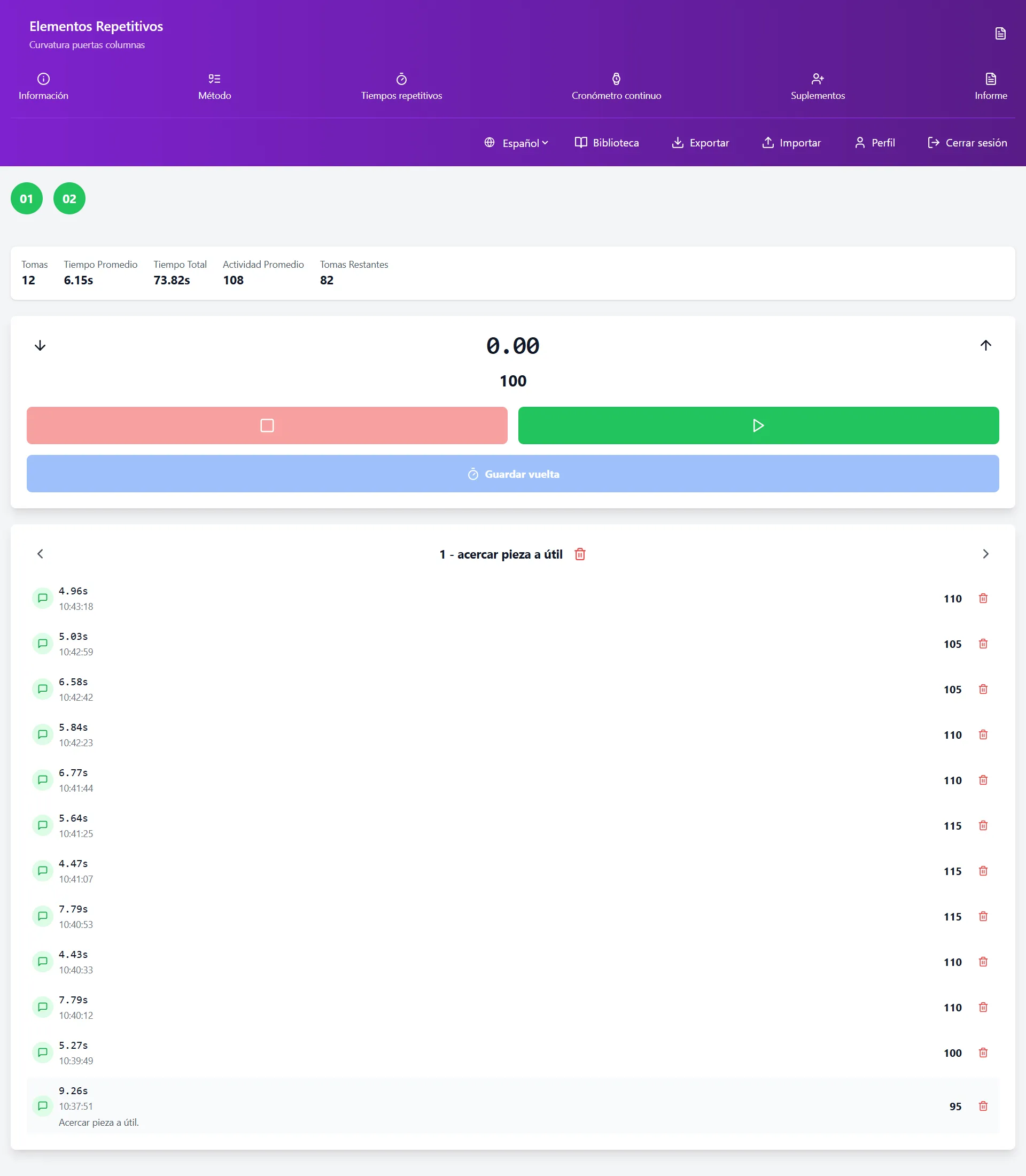

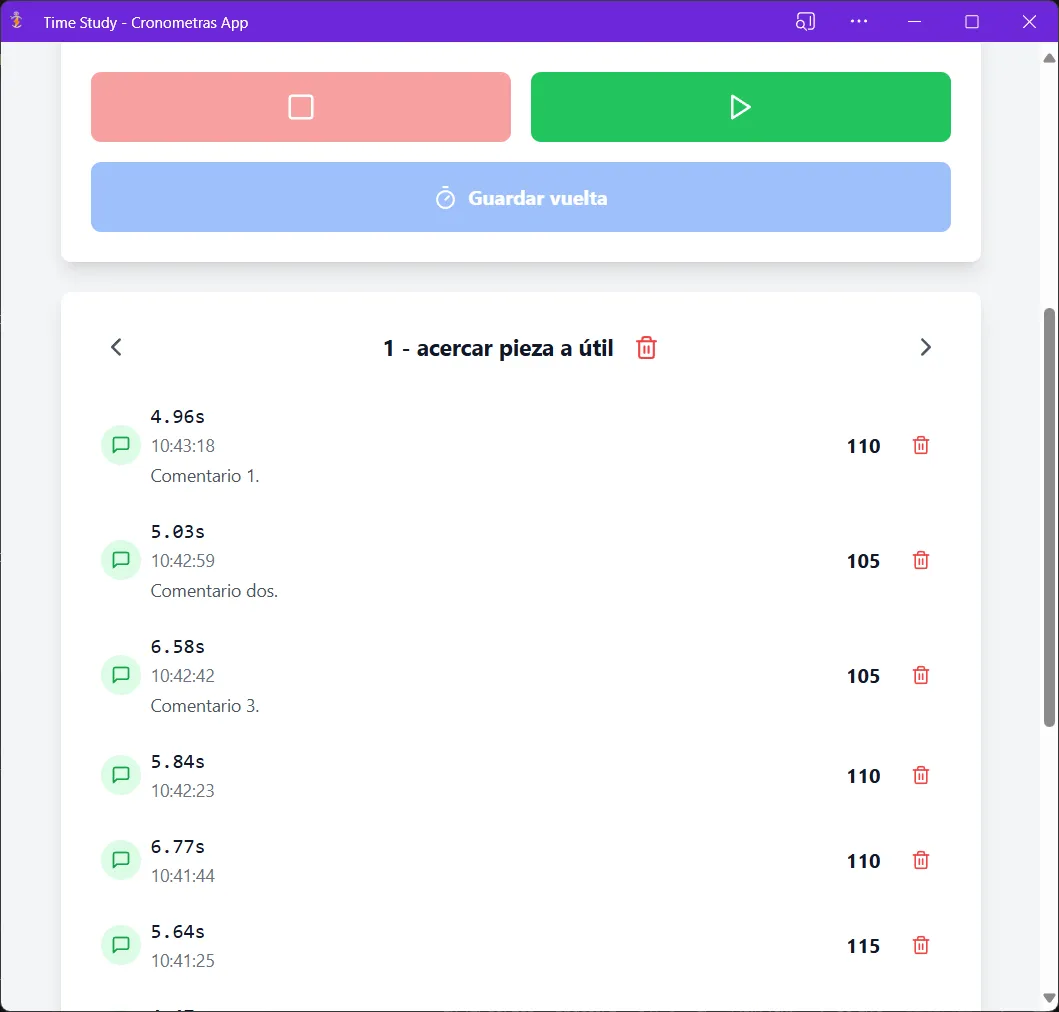

Advanced Observation Management for Documented Time Studies

A professional time and motion study requires detailed documentation. CRONOMETRAS facilitates comprehensive observation management:

• Add contextual comments to specific cycles to explain variations

• Mark readings for later review, creating an organized workflow

• Identify and justify outlier values with explanations that enrich the analysis

• Document special conditions affecting performance (materials, tools, etc.)

• Record relevant environmental factors for allowance application

Maintain a complete and detailed record of your study for subsequent analysis, audits, and justification of standards to management or union representatives.

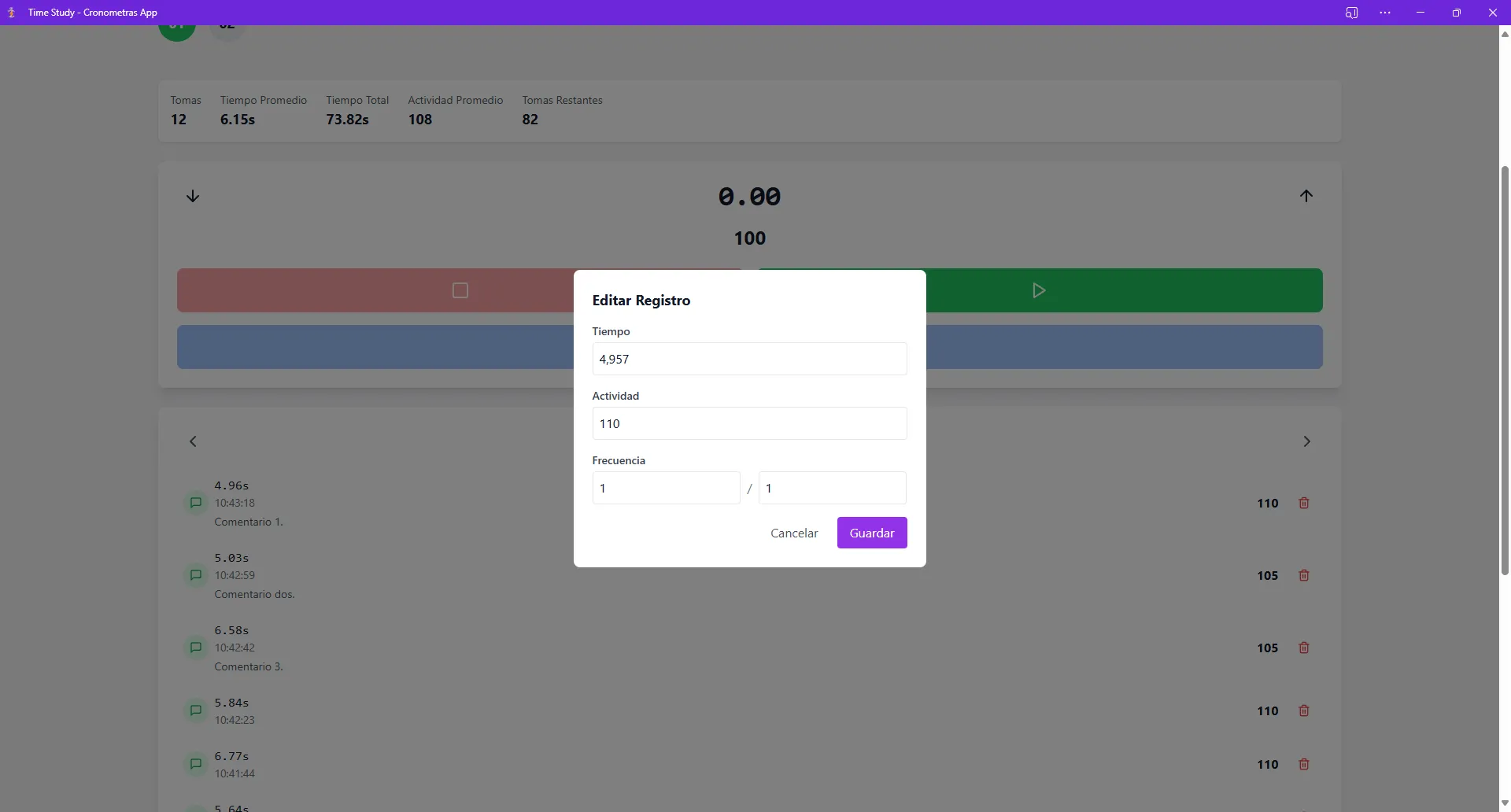

Total Control in Record Editing for Accurate Time Studies

Precision in industrial time study requires the ability to correct and adjust. CRONOMETRAS offers complete control over captured data:

• Edit the time record to correct timing errors or compensate for delays

• Adjust the activity rating after a more detailed review of performance

• Modify the number of pieces processed in each take for accurate productivity calculations

• Selectively delete takes from the record list when they are invalid or non-representative

• Document each modification to maintain study traceability

Don't lose valuable records due to small measurement errors. Maintain total control over time study data without compromising methodological integrity or statistical reliability.

Optimize Your Time Studies with CRONOMETRAS

The CRONOMETRAS Repetitive Times Module represents a significant advancement in industrial time study technology. Unlike traditional methods, our software allows you to:

- Automate the timing sequence to eliminate errors and improve concentration

- Statistically analyze your data in real-time to ensure reliability

- Detail every observation for complete and auditable studies

- Adapt the measurement process to real plant conditions

- Edit and adjust records with total control and traceability

According to recent studies on industrial productivity, companies that implement advanced work measurement systems like CRONOMETRAS manage to reduce the time needed to conduct time studies by up to 35% and improve the accuracy of their standards by 28%, which directly translates into improvements in productivity and competitiveness.

Resources on Industrial Time Study

Lean Manufacturing and Agile Methodologies

Lean Manufacturing and Agile MethodologiesBenefits and Challenges of Implementing Lean Manufacturing in Your Company

Industrial Time Study

Industrial Time StudyIndustrial Timekeeping 4.0: How to Use CronometrasApp to Ensure Statistical Precision and Regulatory Compliance (ISO/ILO)

Industrial Time Study

Industrial Time StudyNumber of Observations Required in Industrial Time Study

Industrial Process Optimization

Industrial Process Optimization