Reports Module: Comprehensive Time Study Analysis

Visualize, analyze, and export the final results of your time studies with key metrics for decision-making in industrial environments.

What is the Reports Module in CRONOMETRAS?

The Reports Module is an essential tool within CRONOMETRAS that provides comprehensive and detailed analysis of time and motion studies. This tool allows you to visualize, analyze, and export the final results of a study, offering key metrics for decision-making in industrial environments and facilitating accurate standard time calculation.

Parameter Configuration for Precise Time Studies

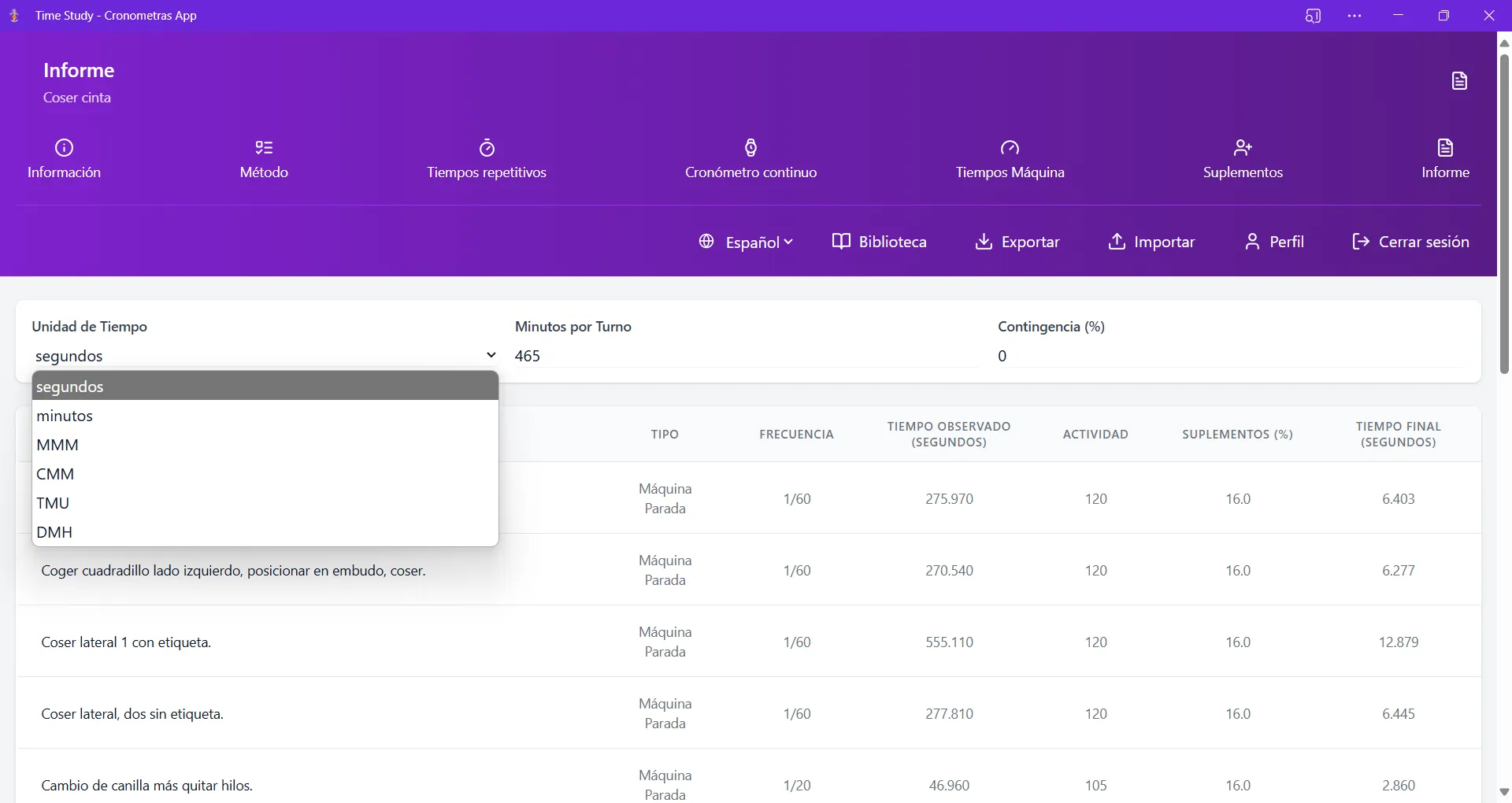

Professional industrial time study requires flexible configuration to adapt to different production environments:

- Time Units: Selection between different standard industry units (seconds, minutes, thousandths of a minute, hundredths of a minute, TMU, DMH) to adapt to the conventions of each sector.

- Shift Duration: Customizable configuration in minutes to accurately calculate production per shift according to the specific schedules of each plant.

- Contingency: Percentage adjustment to consider unforeseen events in the production process, ensuring realistic and achievable standards.

- Automatic Loading: Intelligent retrieval of user preferences from their profile in the database to streamline the configuration process.

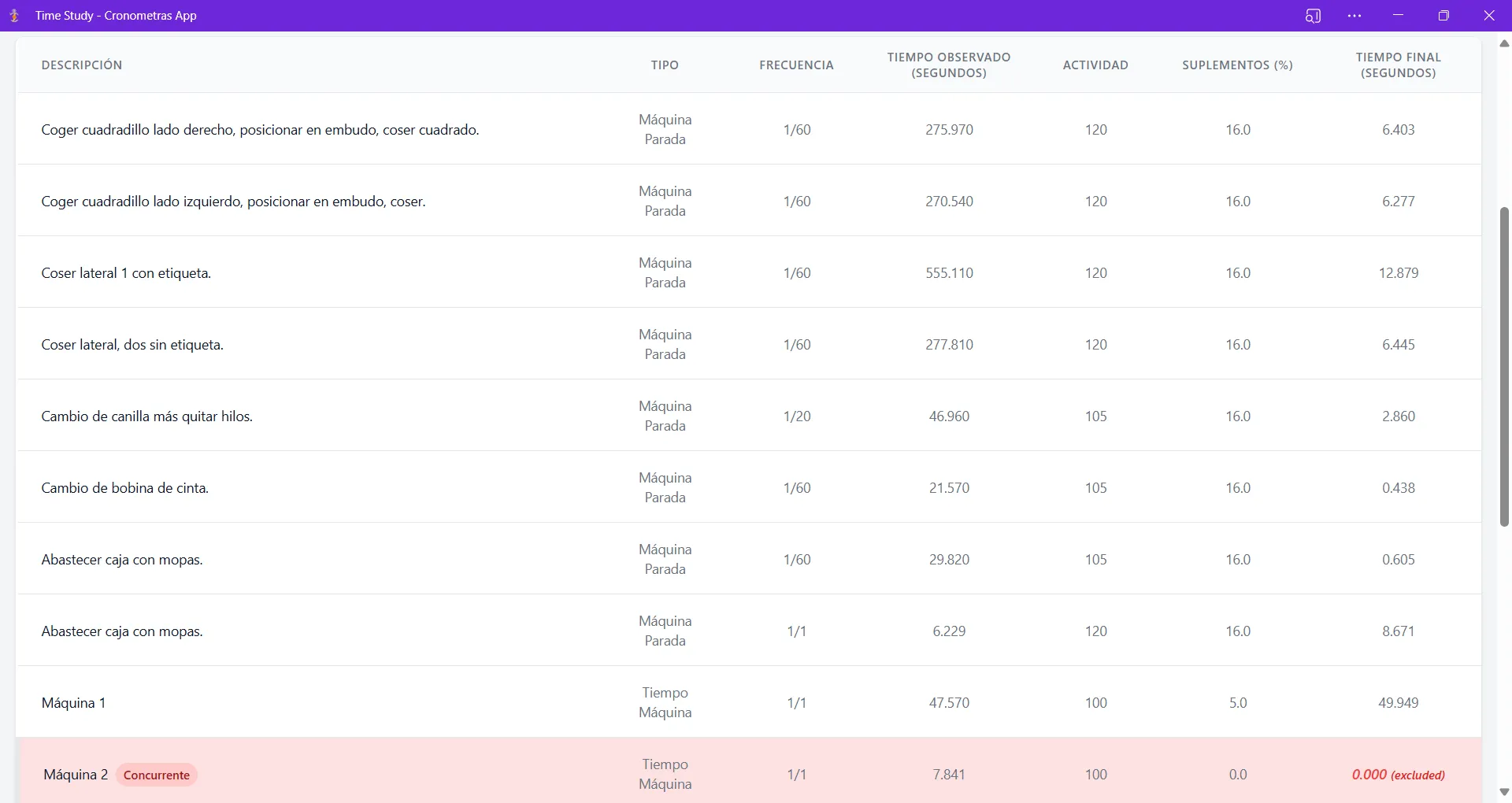

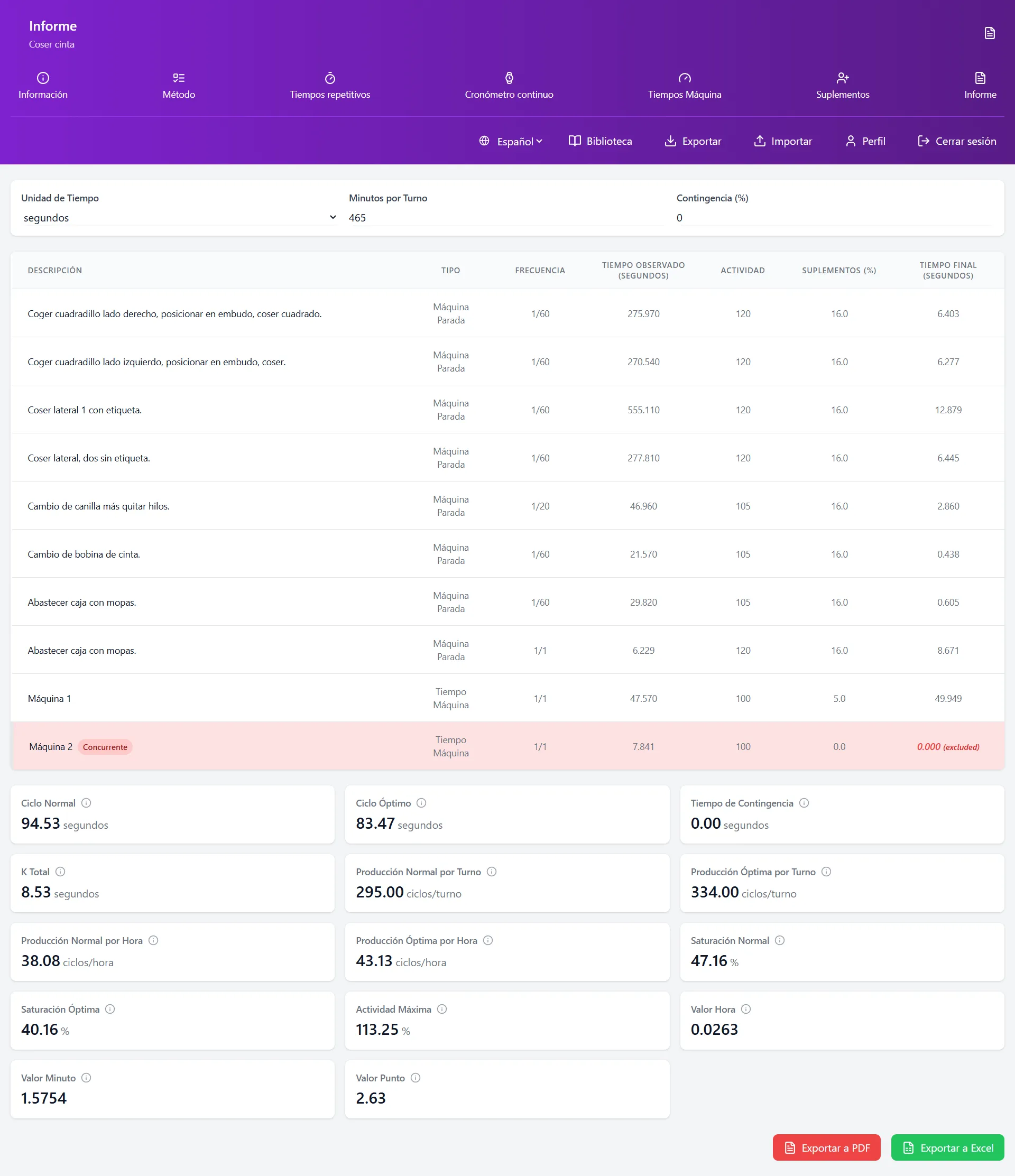

Elements Table for Detailed Time Analysis

Effective work measurement requires clear visualization of all elements and their times:

- Complete Visualization: Presentation of all study elements with their characteristics and times in a clear and structured format.

- Detailed Information: Each element displays its description, type, frequency, observed time, activity, allowances, and calculated final time.

- Visual Identification: Concurrent machine elements are highlighted with a special format (red background) for easy identification.

- Automatic Exclusion: Concurrent machine elements are shown in the table but automatically excluded from total calculations to avoid duplications.

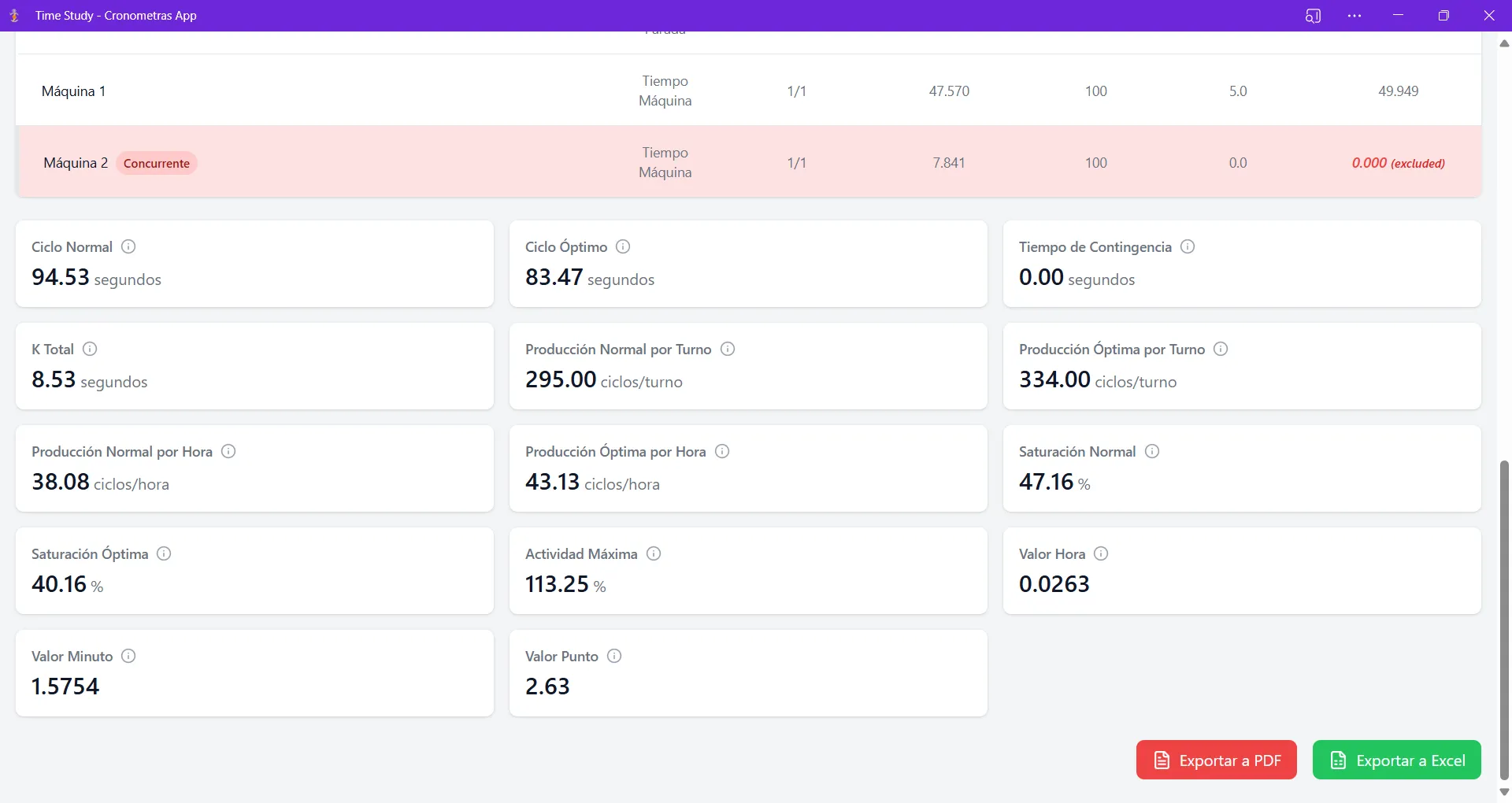

Study Results for Accurate Standard Time Calculation

The industrial time study software CRONOMETRAS provides key metrics for decision-making:

- Work Cycles: Precise calculation of normal and optimal cycle from measured elements, adjusted by frequency, activity, and allowances.

- Contingency Times: Automatic calculation of additional time based on the configured contingency percentage.

- Estimated Production: Projection of production per shift and per hour, both under normal and optimal conditions.

- Saturation: Percentage indicator of operator saturation working at normal and optimal pace, fundamental for line balancing.

- Maximum Activity: Relationship between normal and optimal cycle to calculate the maximum performance achievable by the worker.

- Reference Values: Data per hour, minute, and point to facilitate subsequent calculations and comparisons between studies.

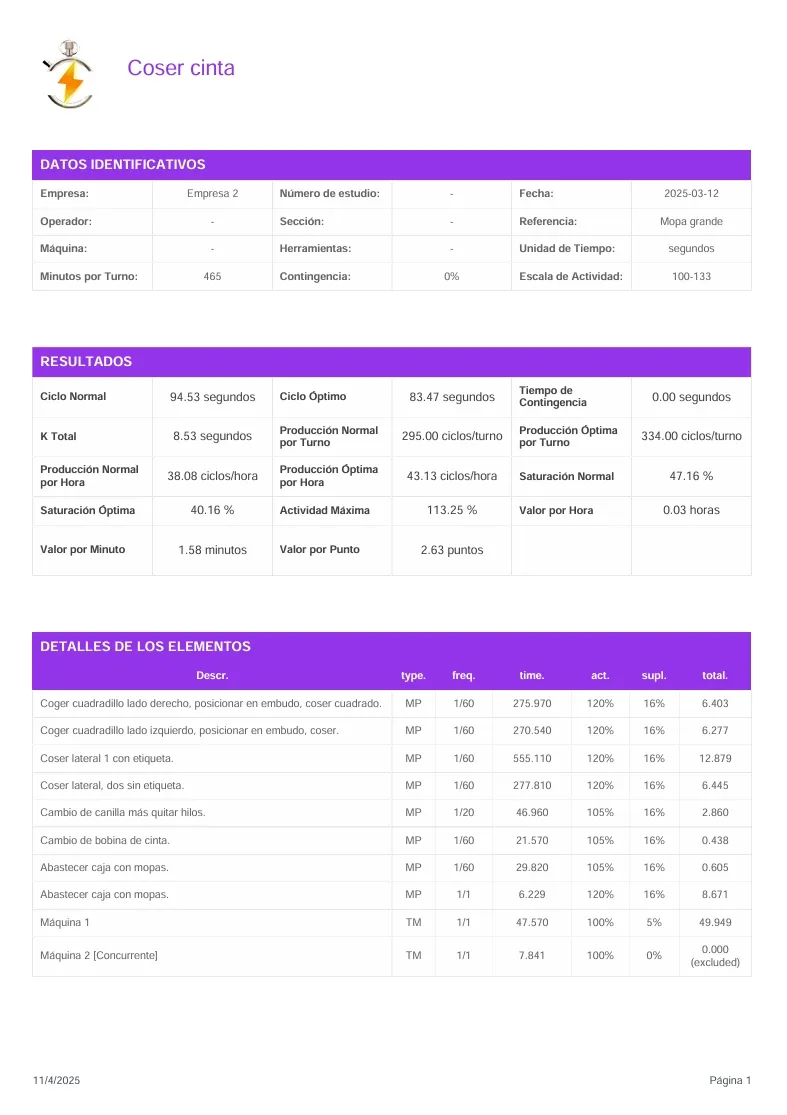

Data Export for Advanced Analysis

The standard time calculation tool includes powerful export options for documentation and additional analysis:

- PDF Generation: Creation of comprehensive reports in PDF format with all study data, ideal for official documentation and presentations.

- Excel Export: Conversion of all data to Excel spreadsheets with included formulas and calculations for additional analysis.

- Corporate Customization: Automatic inclusion of company logo and study identification data in generated reports.

- Professional Format: Structured and professional design that facilitates data understanding and improves presentation to clients and executives.

Advanced Calculations for Precise Time Studies

For high-precision time and motion studies, CRONOMETRAS implements advanced calculations:

- Frequency Adjustment: Precise consideration of each element’s frequency in the total cycle for a realistic standard time calculation.

- Activity Normalization: Automatic adjustment of times according to the observed activity and the activity scale configured in the study.

- Applied Allowances: Incorporation of allowances assigned to each element to obtain fair and realistic standard times.

- Machine Element Management: Application of specific rules to correctly calculate the total cycle with concurrent machine elements.

- Unit Conversion: Complete conversion system between different industrial time units (seconds, minutes, MMM, CMM, TMU, DMH).

Optimize Your Time and Motion Studies with CRONOMETRAS

The Reports Module of CRONOMETRAS is essential for completing the cycle of your time and motion studies. Unlike traditional industrial time study methods, our software allows you to:

- Configure parameters adapted to the specific needs of your industry

- Visualize all study elements with their times and characteristics

- Obtain key metrics such as normal cycle, estimated production, and saturation

- Export professional reports in PDF and Excel for documentation and analysis

- Perform advanced calculations that consider frequency, activity, and allowances

According to recent studies on industrial productivity, companies implementing advanced work measurement systems like CRONOMETRAS achieve up to 25% reduction in time dedicated to report generation and 30% improvement in the accuracy of their production estimates.

Resources on Time Analysis and Productivity

Industrial Engineering

Industrial EngineeringOEE Calculation in Production Lines: Why Your Performance Factor is Fake Without Methods Engineering (ISO 22400 Analysis)

Industrial Time Study

Industrial Time StudyImpact of Ergonomics on Cycle Times: From Variable Fatigue to Maximized OEE (Horizon 2025)

Industrial Time Study

Industrial Time StudyIndustrial Productivity Consulting: The Cronometras Approach to Operational Excellence

Management

Management