Machine Times Module

Record and analyze the exact times of your machinery operations with the Machine Times Screen and optimize your industrial productivity.

What is the Machine Times Screen in CRONOMETRAS?

The Machine Times Screen is a specialized tool within the Cronometras application that allows users to record and analyze specific times related to machinery operations in method and time studies. This functionality is designed to study and optimize processes involving machines, thus allowing for the differentiation within the study between machine stopped times, machine running times, and machine cycle times.

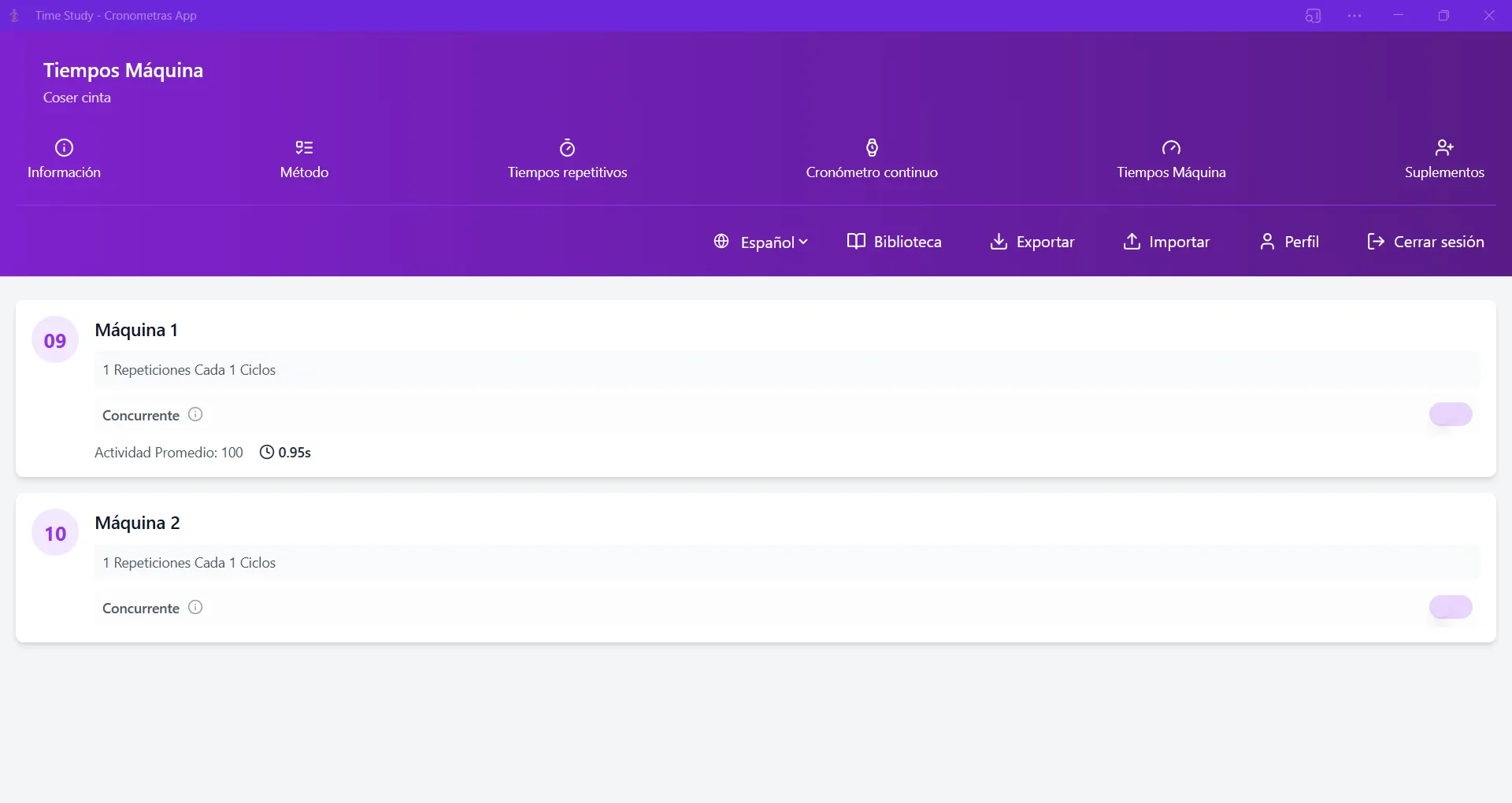

Machine Element Management

Precisely control operation times in your method and time studies:

• Complete list of machine-time type elements defined in the study

• Visualization of statistics with average time and average activity

• Selection of specific elements to perform measurements

• Configuration of repetition and cycle frequency

Clearly differentiate between machine stopped times, machine running times, and cycle times in your industrial time studies.

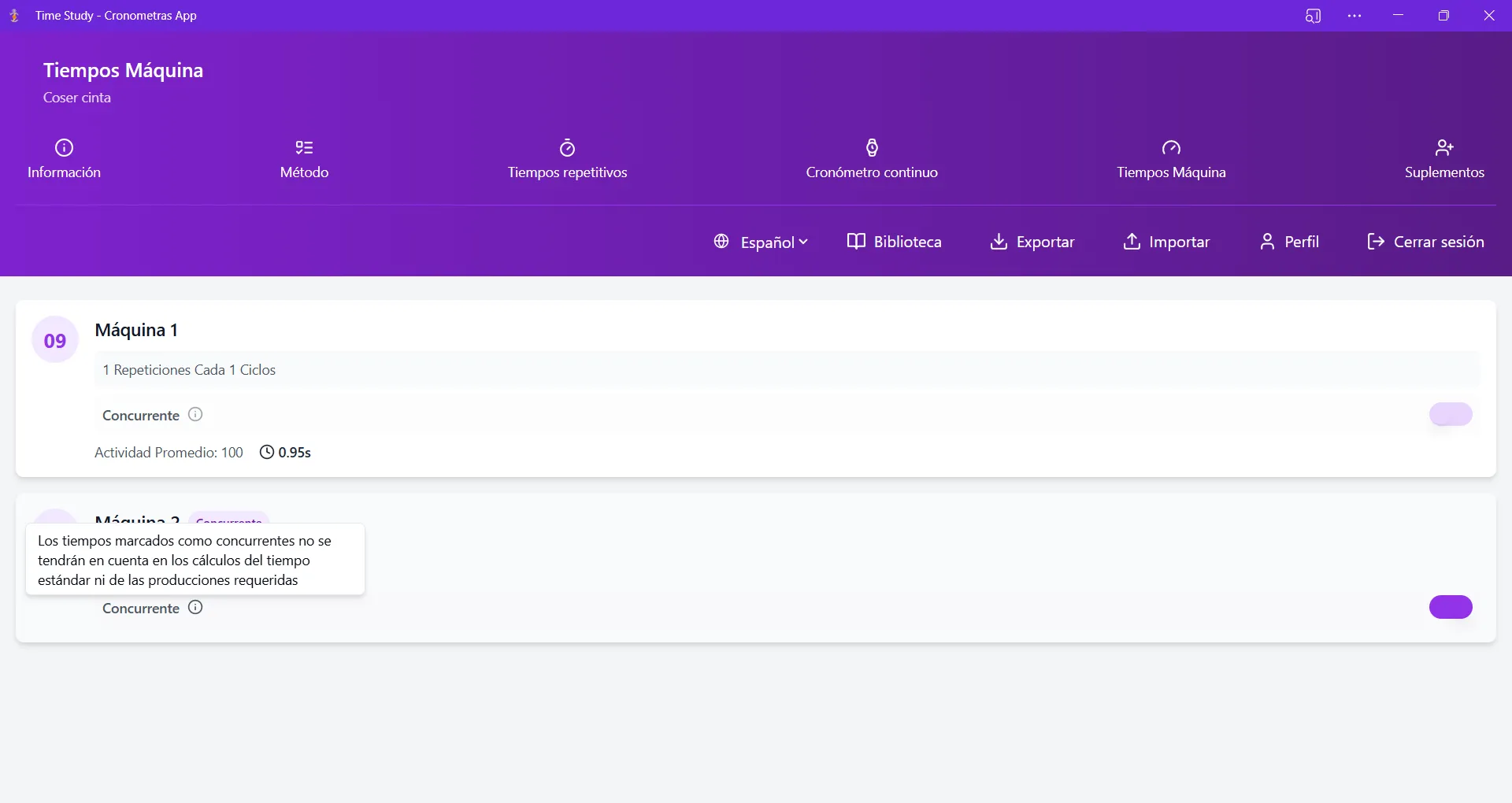

Concurrent Machine Times

Identify simultaneous operations in your time study:

• Concurrent mode to mark elements that occur simultaneously

• Visual indicator with purple background for easy identification

• Contextual help about the purpose of concurrent times

• Identification of elements that do not affect standard time

Identify simultaneous processes without affecting the standard time calculation, as the worker does not invest time in them.

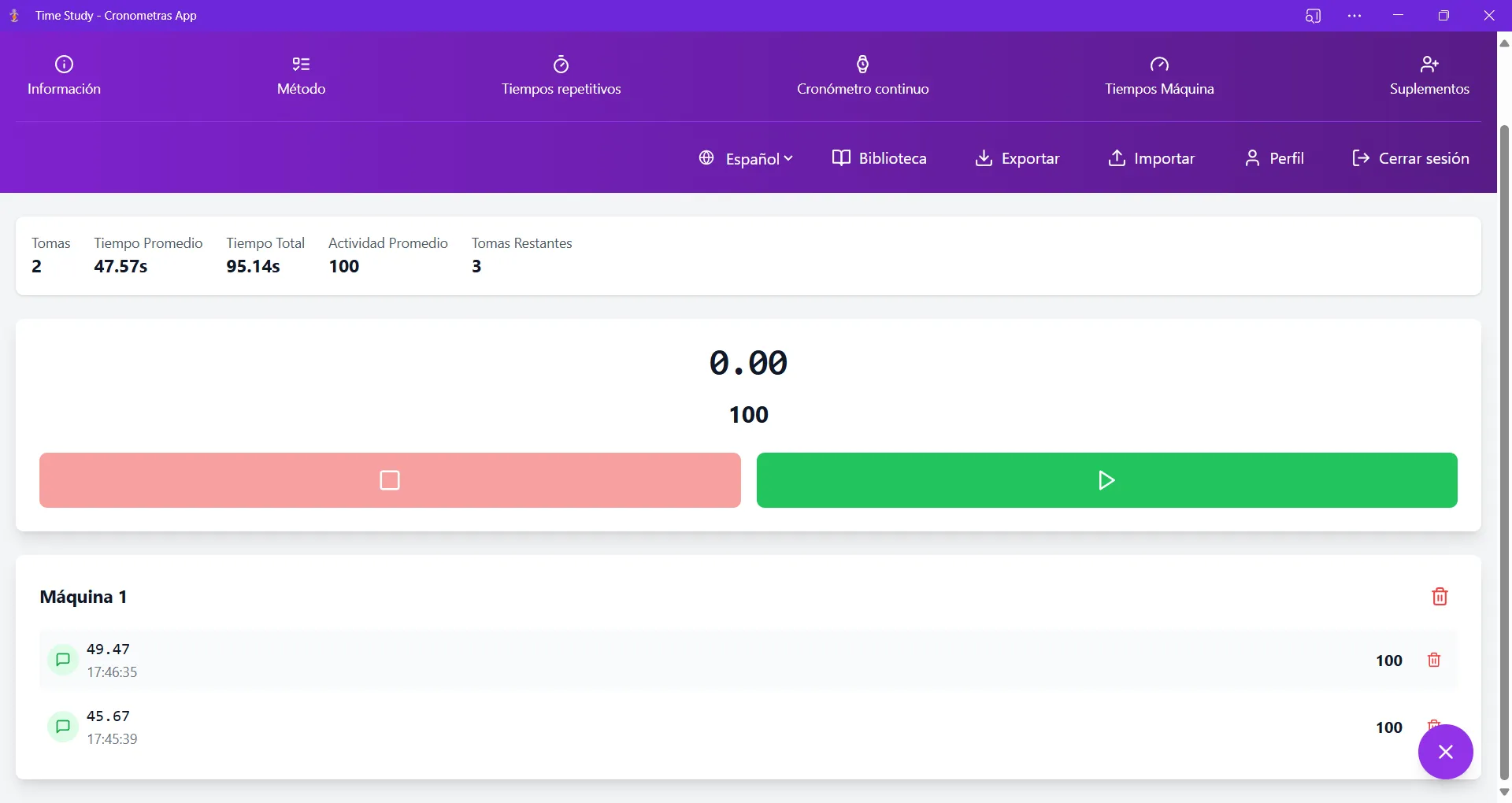

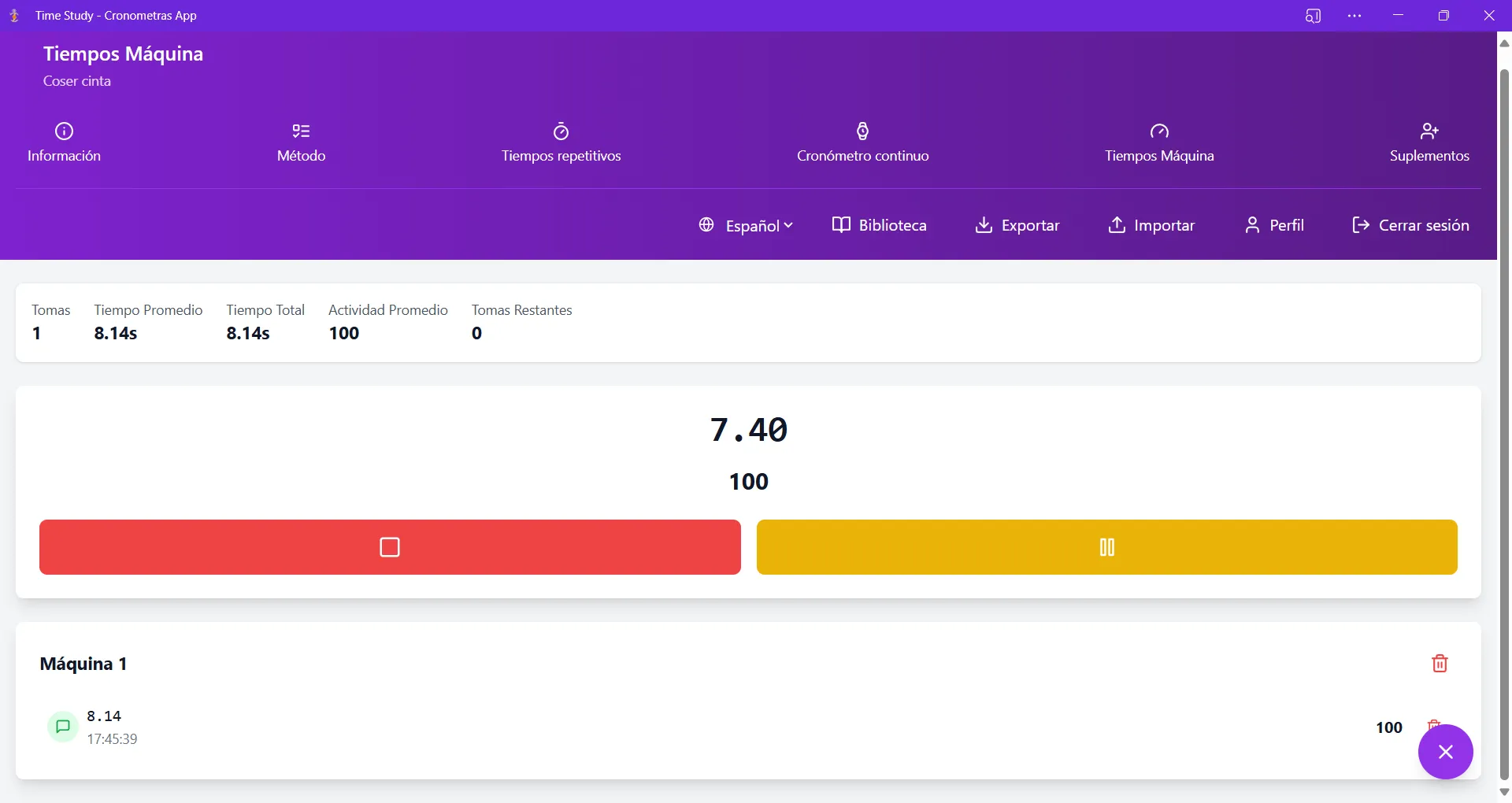

Specialized Stopwatch for Machines

Precise tool for industrial time study of machinery operations:

• Intuitive control with buttons to start, pause, and stop

• Time display with hundredths of a second precision

• Design adapted for machine times without activity rating

• Sensory feedback with auditory and haptic response

Perform precise machine time measurements to establish reliable standards in your method and time studies.

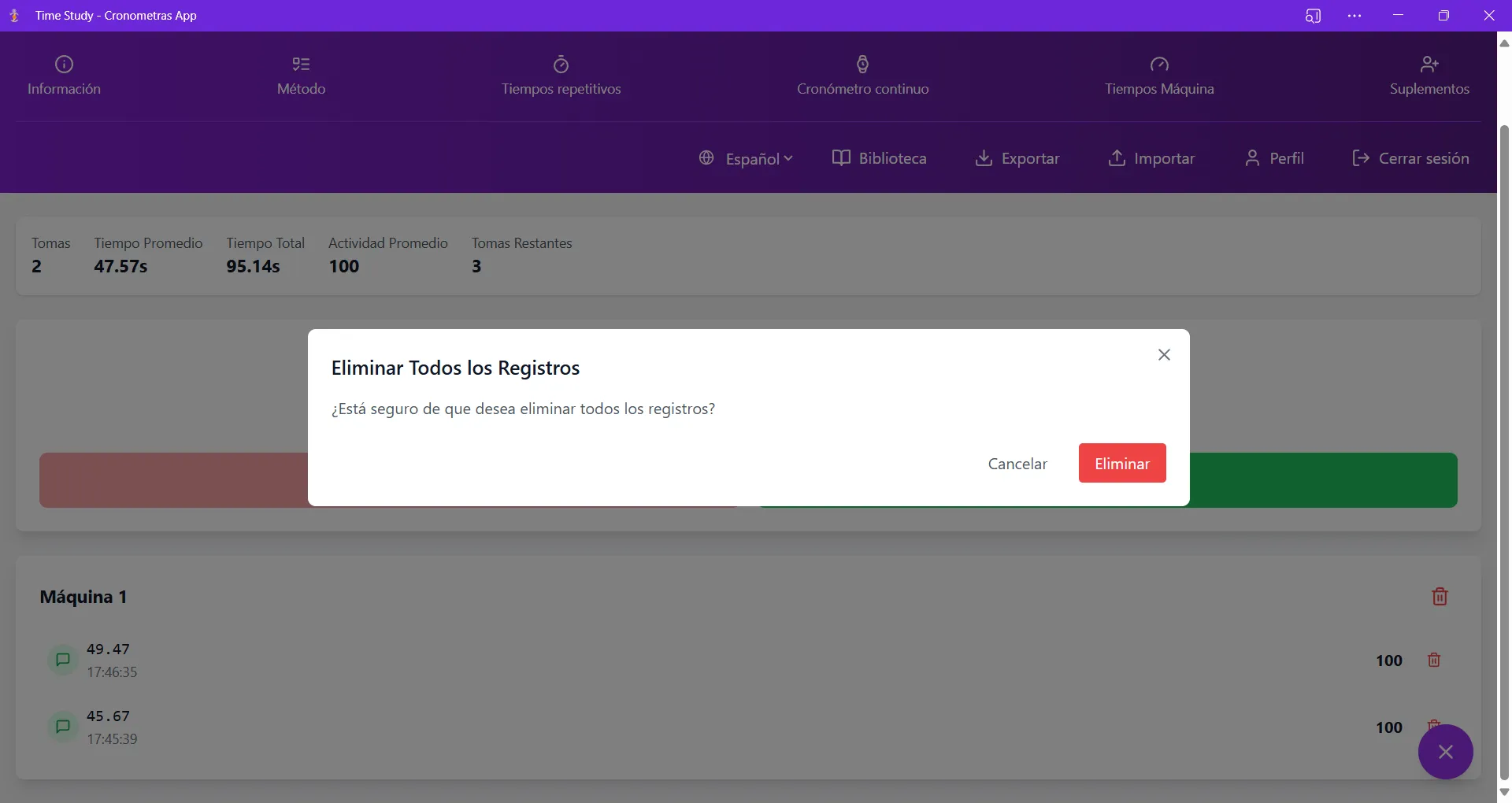

Advanced Time Record Management

Efficiently manage your time study data:

• Chronologically ordered list of records (most recent first)

• Individual editing of time, activity, and frequency for each record

• Options to delete individual records or all at once

• Comments via text or voice recognition

Keep your method and time studies organized and accurate for optimal standard time calculation.

Frequency Adjustment and Standard Time Calculation

Optimize the precision of your measurements for standard time calculation:

• Configuration of repetitions per cycle and cycles per measurement

• Automatic recalculation based on the formula T'_o = T_o × (N_e/N_r)

• Precise adjustment between observed time and expected time

• Integration with the overall standard time calculation

Obtain precise standard times that accurately reflect the reality of your industrial processes.

Optimize Your Method and Time Studies with CRONOMETRAS

The CRONOMETRAS Machine Times module is a specialized tool within our industrial time study software that allows industrial engineers, method and time technicians, and production managers to conduct precise studies of operations involving machines. Unlike traditional methods, our software allows you to:

- Clearly differentiate between machine stopped times, machine running times, and machine cycles

- Identify concurrent times that do not affect standard time calculation

- Perform measurements with hundredths of a second precision

- Manage and edit time records with comments and classifications

- Automatically adjust times based on configured frequencies and cycles

The Machine Times screen integrates seamlessly with the rest of the method study, utilizing the elements defined in the method, storing all records in the study’s data structure, and contributing to the global analysis to identify bottlenecks or inefficiencies in machine-related processes.

According to recent studies on industrial productivity, companies that implement advanced work measurement systems like CRONOMETRAS manage to establish standard times up to 30% more accurate and increase their overall productivity by 15-20%.

Resources related to Method and Time Studies

Work Study

Work StudyWork Sampling: A Statistical Tool for Efficient Management

Concepts and Fundamentals

Concepts and FundamentalsObjectives of Work Study

Industrial Time Study

Industrial Time StudyWork Sampling: Analyst's Guide to Statistical Precision and Process Optimization (ILO Standard)

Methodology

Methodology