Industrial time study is a tool used in industry to measure the time elapsed during a production process or the time spent by a worker on a specific task. This information is fundamental for production management and efficiency improvement, as it allows companies to optimize their processes and increase productivity.

Industrial Time Study Systems

There are different industrial time study systems available, each with its own characteristics and advantages. Some examples include:

-

Manual time study (using a stopwatch or other device such as the industrial time study app from cronometras.com that allows for precise time measurement. The observer must also assess the activity or work pace of the operator, that is, the speed at which they perform the task in relation to normal or required activity, this will give us the normal or normalized time.)

-

Automatic time study (using electronic devices or software)

-

Radio frequency time study using devices that send and receive radio signals to measure the time of an activity, there are two types of radio frequency time study: active and passive.

- The active uses chips that work with batteries and transmit signals to receivers and decoders.

- The passive uses chips that do not have a battery and only respond when they are read by a reader.

To measure production time in a factory, it is important to establish a consistent and accurate time study method. This should include defining start and end points for each process or task, as well as identifying the activities that should be included in the calculation of time. It is also important to take into account pauses and downtime that may affect the total production time.

Benefits of Using Industrial Time Study in Production Management

There are many benefits of using industrial time study in production management. Some of them include:

-

Establishing more efficient and safer work methods. It allows companies to measure and compare the efficiency of different processes and tasks, which facilitates the identification of areas for improvement.

-

Planning and controlling production. It helps companies establish more realistic production goals and objectives and meet established delivery deadlines.

-

Calculating the costs and prices of products or services. It provides valuable information for decision-making in terms of investment in equipment and machinery.

-

Designing incentive or bonus systems for workers.

-

Evaluating the performance and productivity of operators.

-

It allows companies to improve the utilization of time and production capacity, which translates into cost savings.

Common Errors in Implementing an Industrial Time Study System

However, it is important to note that industrial time study can also present some challenges. One of the most common errors is the lack of precision in time measurement, either due to a poor definition of start and end points or a lack of attention to detail in time recording.

Another common error is the excessive emphasis on maximizing productivity at the expense of quality and safety, which can lead to rushed and unsafe work.

One way to avoid these errors is to implement a time study system in a careful and planned manner, taking into account all relevant variables and establishing a consistent measurement and recording process. It is also important to involve workers in the implementation and use of the system, as they can provide valuable information and contribute ideas to improve efficiency.

Disadvantages

Industrial time study is a fundamental tool for improving the competitiveness and profitability of companies. However, it also involves some disadvantages such as:

-

It requires qualified and trained personnel to correctly perform measurements and analyses.

-

It can generate resistance or distrust from workers if they are not adequately informed of the purpose and benefits of the study, for this reason, it is convenient to provide training to the staff.

-

It can be difficult to apply it to complex, variable, or creative tasks that cannot be easily standardized.

Therefore, it is important to combine industrial time study with other complementary techniques such as motion study, bimanual diagram, or statistical analysis. This will provide a more complete and accurate view of the actual work performed by operators.

Trends in Industrial Time Study

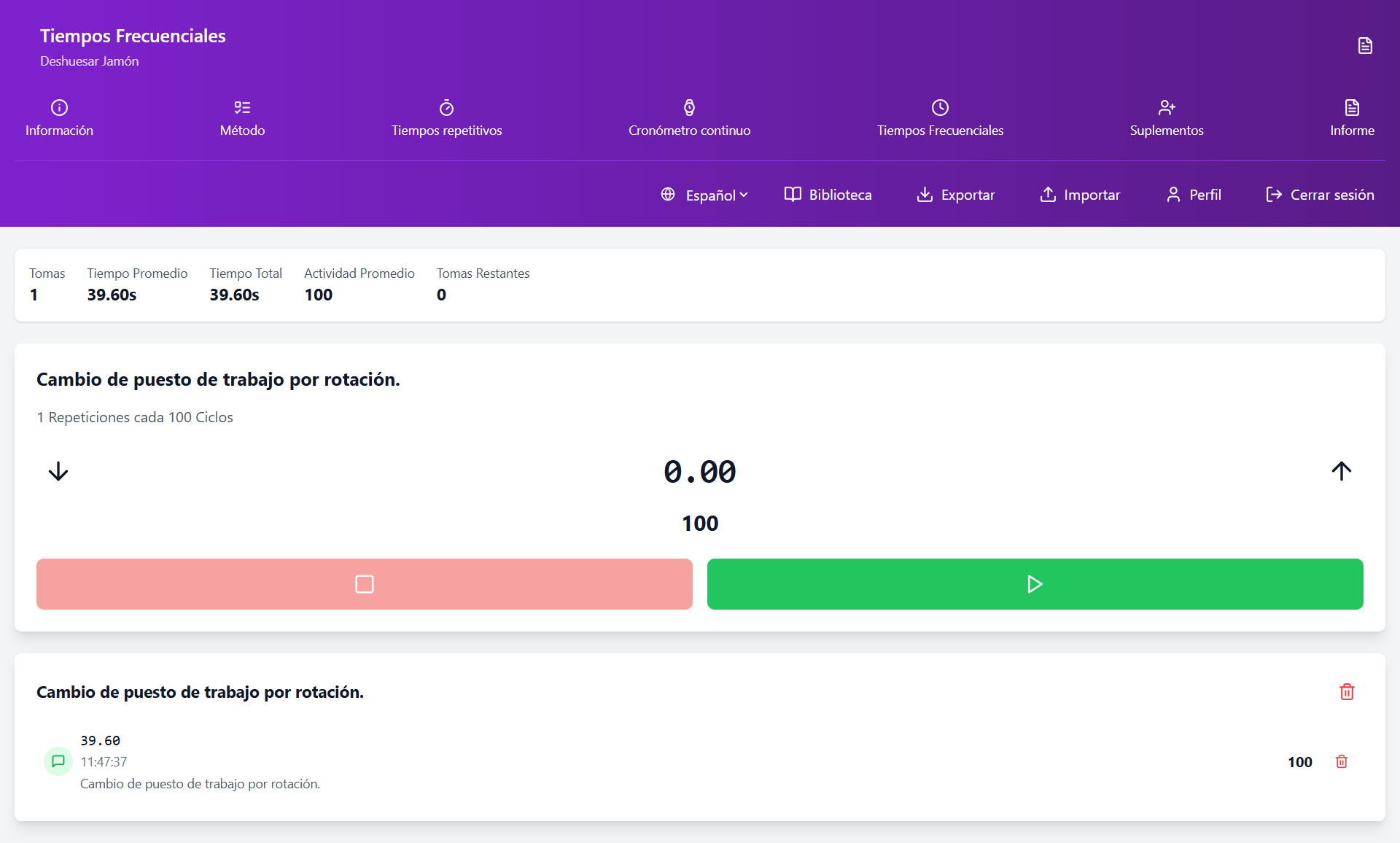

Regarding trends in industrial time study, we can expect to see greater use of advanced technology and software solutions in the future. This includes the implementation of automated time study systems and the use of mobile devices and applications for time measurement and tracking such as CronometrasApp. We can also expect to see a greater emphasis on integrating industrial time study with other production management tools, such as real-time production tracking and quality management.

Choosing an Industrial Time Study System

When it comes to choosing an industrial time study system, it is important to compare the different options available and choose the one that best suits the company’s needs. Each time study method has its own advantages and disadvantages, and it is important to consider factors such as accuracy, ease of use, cost, and adaptability to the specific needs of the company.

For example, manual time study may be more economical, easy to use, and implement in different industrial sectors, but it has the disadvantage that it may require more time and effort to record and analyze the data, to solve this inconvenience the App from cronometras.com was born.

For those interested in obtaining more information and training in industrial time study, there are many options available, such as online courses, certification programs, and in-person workshops. These can provide a deeper understanding of key concepts and best practices in the use of industrial time study in industry.

Industrial time study is a valuable tool in production management and efficiency improvement. With its proper use and adequate training, companies can make the most of its benefits and optimize their production processes to increase productivity and reduce costs.

If you want to know more about industrial time study or need professional help to apply it to your company, do not hesitate to contact us. We are experts in industrial process optimization and offer customized solutions adapted to your specific needs.