Bedaux Scale (60/80) vs. ILO Centesimal (100/133): Why Industry 4.0 Demands Abandoning the Bedaux System

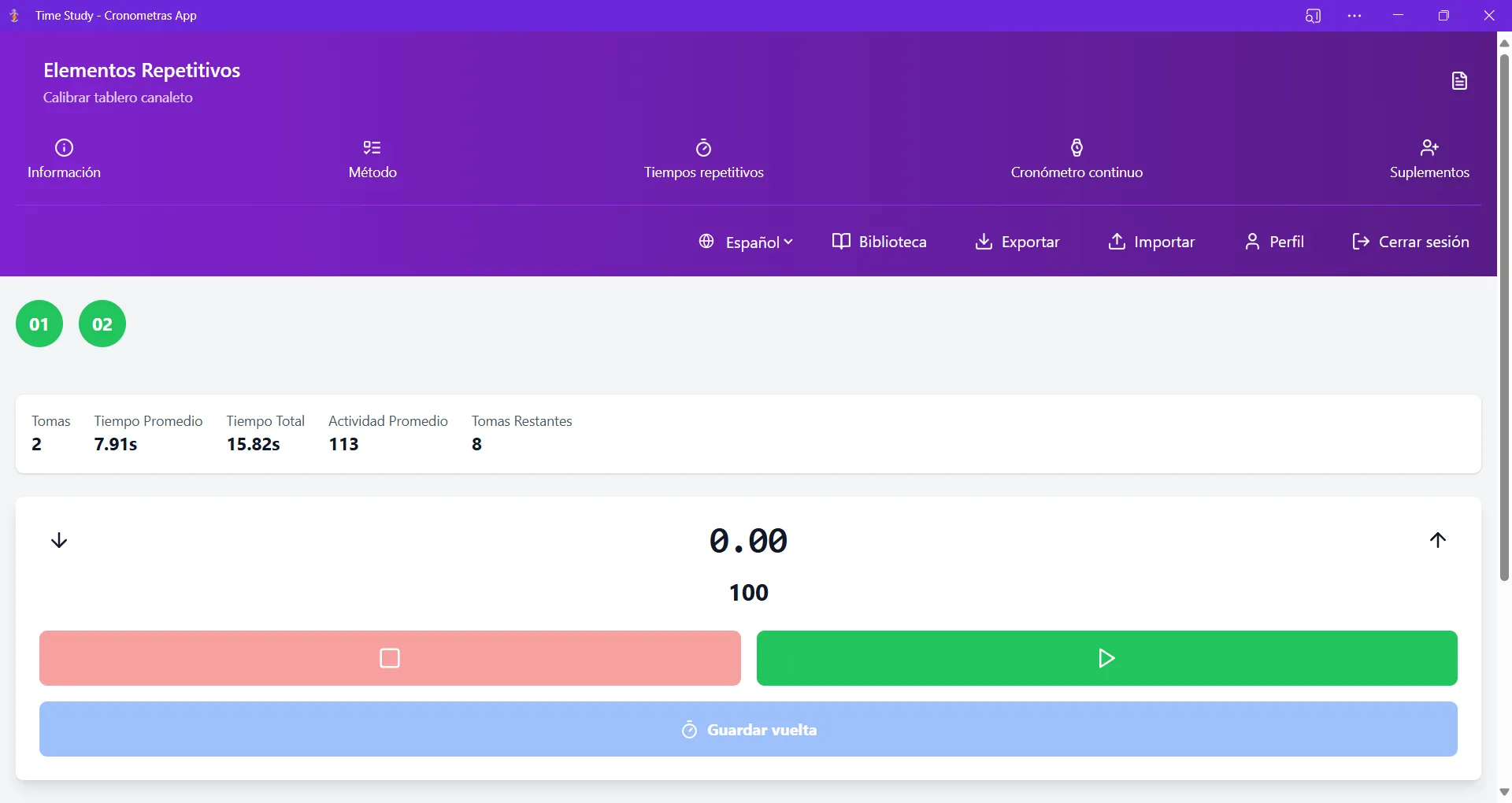

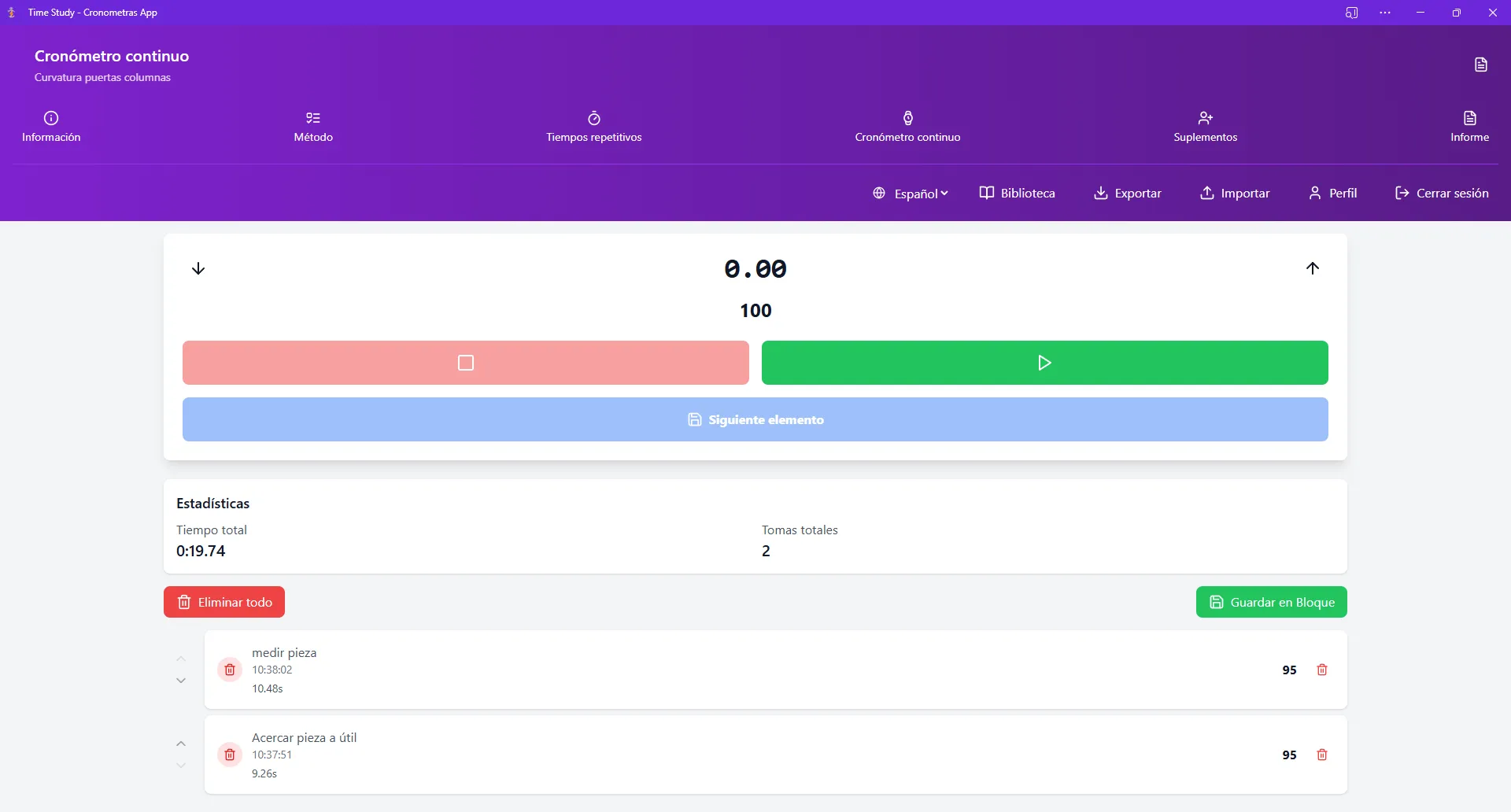

In the world of industrial engineering, few topics spark as much debate as the choice of timing scales. While many plants in Europe and South America still cling to the Bedaux System (60/80), the global standard has shifted decisively towards the Centesimal Scale (100/133) recommended by the ILO (International Labour Organization).

1. What are these scales?

The Bedaux Scale (60/80)

Developed by Charles Bedaux in the early 20th century, it defines:

- 60: Normal activity (the pace of a motivated worker without incentives).

- 80: Optimal activity (the pace achievable with incentives, roughly 33% faster).

The Centesimal Scale (100/133)

The modern standard defines:

- 100: Normal activity.

- 133: Optimal activity (maintaining the same 33% proportionality).

2. Mathematical Analysis and Conversion Table

The relationship between both scales is perfectly linear, but the Bedaux scale introduces “measurement noise” due to its lower resolution.

Conversion Formulas:

| Concept | Bedaux (60/80) | Centesimal (100/133) |

|---|---|---|

| Normal Activity | 60 | 100 |

| Optimal Activity | 80 | 133 |

| Midpoint | 70 | 116 |

3. Why Bedaux is Obsolete in Industry 4.0

Lack of Resolution

Between 60 and 80 Bedaux, there are only 20 units. Between 100 and 133 Centesimal, there are 33. The Centesimal scale offers 65% more granularity, which is vital when measuring high-speed automated processes or micro-movements.

Incompatibility with MES/ERP

Most modern production management systems (SAP, Oracle, specialized MES) naturally use decimal bases. Converting data into “Bedaux Points” adds a layer of calculation that often masks rounding errors and makes it difficult to calculate OEE in real-time.

MTM and MOST Integration

Predetermined time systems like MTM-1 or MOST natively generate standards in Centesimal activity (specifically at 100). Forcing an MTM study into a Bedaux scale is mathematically redundant and error-prone.

4. Psychological Impact and Transparency

The Centesimal scale is much easier to explain to Workers’ Committees. Saying a worker is at “110%” is intuitive; saying they are at “66 Bedaux Points” requires constant conversion and promotes mistrust. Transparency is the foundation of any incentive system.

5. Incentive (Bonus) Calculation

In modern systems, the bonus is calculated directly based on the percentage above 100:

This simplicity reduces administrative costs and potential disputes over paycheck calculations.

Conclusion

Transitioning from Bedaux to Centesimal is not just a change of numbers; it is a technological upgrade. It aligns your plant with international benchmarks and prepares your data for the digital era.

Ready to upgrade your measurement system? Our team at Cronometras can help you transition your standards with zero downtime.