Work method study consists of critically examining the way in which a specific task is performed in order to improve this process by creating a more effective one or simplifying the existing one. This technique focuses on measuring and analyzing the time needed to perform each of the tasks involved in a process and identifying opportunities to improve the efficiency and effectiveness of these processes.

Time study will help us identify the standard time or assigned time to perform the task to be measured, following a predefined method, by a qualified operator or one with the necessary training to perform said task, working at a normal pace.

The time standard helps us determine very necessary information for production, such as calculating costs, planning production times needed to serve our customers, number of operators needed, number of machines needed for the process, balancing manufacturing lines, etc.

Some reasons why it is important to conduct a methods and time study in a company:

-

Identify and eliminate unnecessary processes: A methods and time study allows identifying processes that do not add value to the product or service, which can lead to the elimination of these unnecessary tasks. This in turn reduces costs and improves efficiency in the company.

-

Improve efficiency and productivity: By measuring the times and movements of workers, the production process can be analyzed and determined how to make it more efficient. The elimination of unnecessary tasks, the elimination of unnecessary movements, and the improvement in the sequence of tasks can improve productivity and reduce production time.

-

Establish work standards: The study of methods and times allows establishing work standards for each task involved in a process. This allows workers to know what is expected of them and helps them work more efficiently.

-

Improve quality: By eliminating unnecessary tasks and improving process efficiency, the probability of errors is reduced and the quality of the product or service is improved.

-

Reduce costs: By improving efficiency and productivity, production costs are reduced and the profitability of the company is improved.

With this technique, we can increase productivity through a reorganization of work, making it safer through a standardization of the method. This contributes to improving working conditions and allows setting performance standards and associated incentive systems.

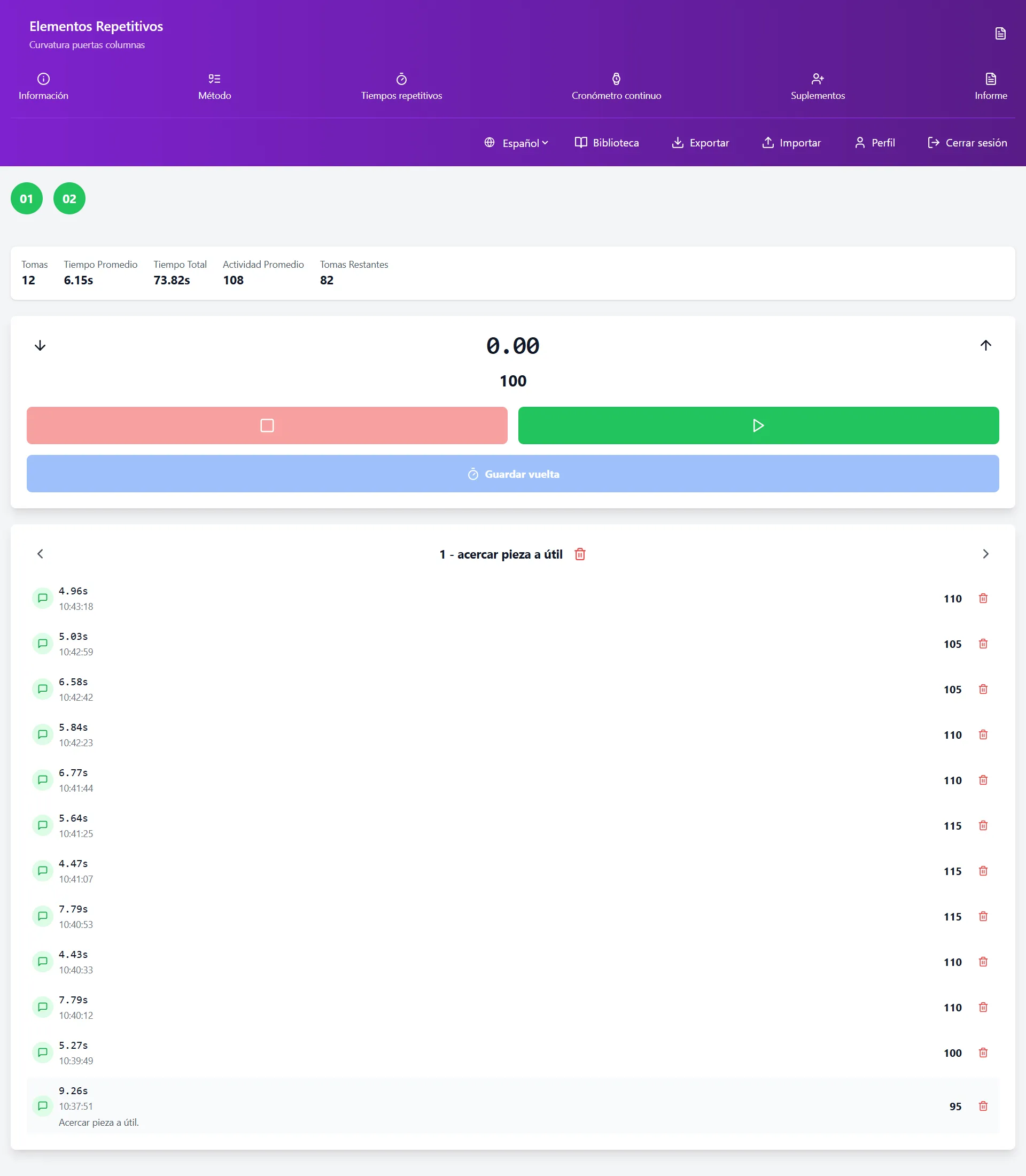

In order to help companies conduct these studies, the cronometras.com app is developed, an application with which you can perform time analysis in an agile and simple way.

Conclusion

Mastering industrial time study techniques is essential for any professional seeking to optimize production processes. The systematic application of these methods not only improves operational efficiency but also contributes significantly to cost reduction and increased business competitiveness. Remember that precision in measurement and rigorous analysis of data are the basis for establishing reliable time standards that drive continuous improvement in your organization.