With the chrono analysis technique, the time needed to perform a specific task is established, by an average worker, with the necessary training to perform that task, following a pre-established method and working at a normal pace, without the stimulus of remuneration with incentives, through the use of a stopwatch or the application of CronometrasApp, specifically designed for this purpose.

The objective is to measure the time used to perform each task and analyze the processes to identify unnecessary times and movements and eliminate them, in order to improve efficiency and reduce costs.

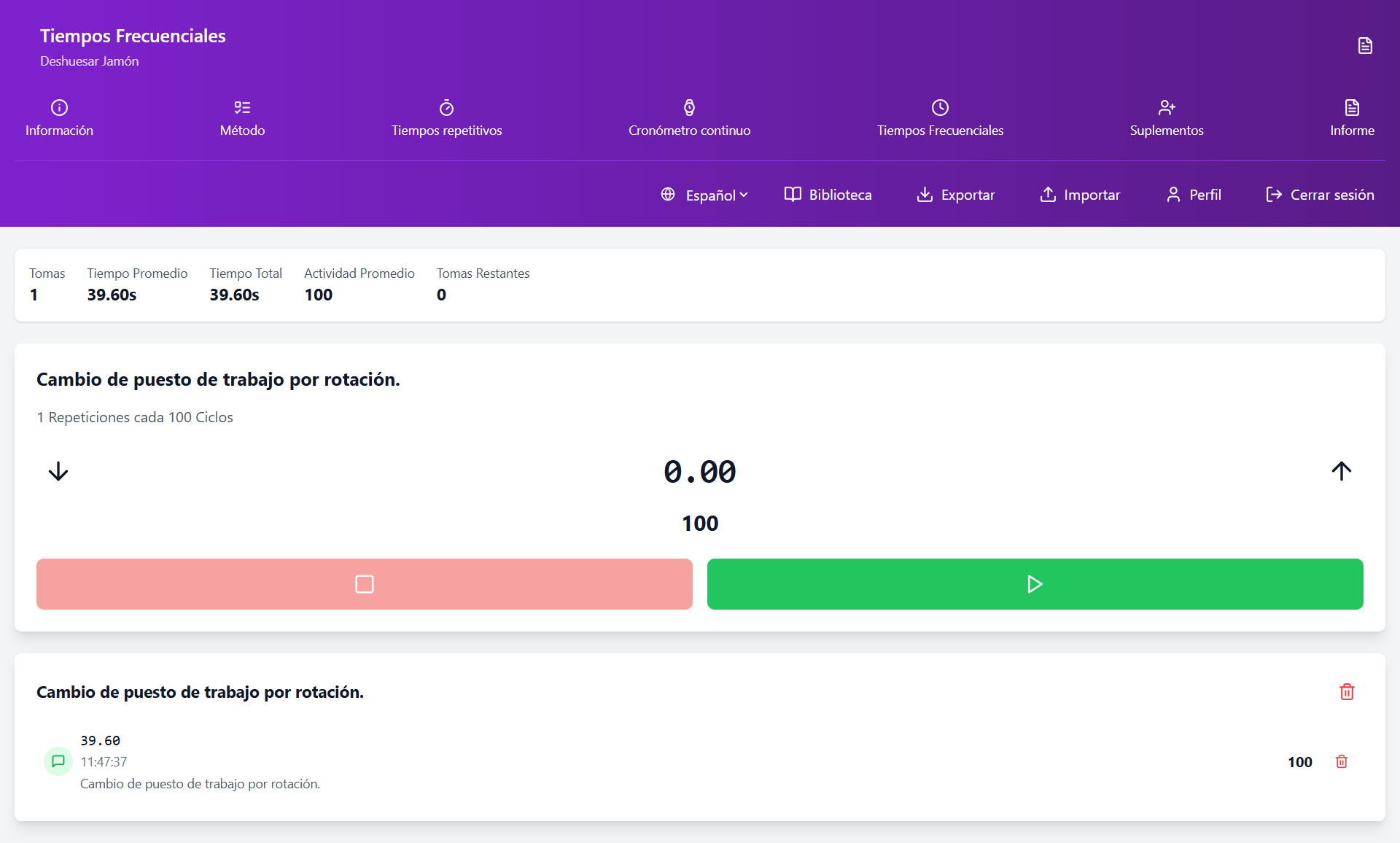

The timing of industrial processes is carried out through direct observation of the process and measurement of the time used to perform each task. Until the appearance of new methods such as the Cronometras.com App, tools such as the classic stopwatch, the time sheet, and movement analysis have been used to measure and analyze the time used to perform a process. The results of the timing are used to establish standard times and to develop better work methods.

The timing of industrial processes is also used to improve safety at work, by identifying and eliminating unnecessary or potentially dangerous movements and times, thus designing safe work methods. In addition, it also helps to improve ergonomics at work, by identifying and eliminating movements and postures that are forced or uncomfortable for the worker.

In summary, the timing of industrial processes is a technique that is used to measure and analyze the time used to perform a specific process in an industry, in order to identify and eliminate unnecessary times and movements, improve efficiency, and reduce costs.

View Quiz

Complete Lesson

Next Lesson

Reset Lesson