OEE Calculation in Production Lines: Why Your Performance Factor is Fake Without Methods Engineering

OEE (Overall Equipment Effectiveness) is the standard KPI for industrial efficiency. However, according to our audits, 60% of factories calculate it incorrectly. Specifically, they fail in the “P” (Performance) factor.

1. The OEE Formula (ISO 22400)

The formula is simple in theory but complex in practice:

Availability (A)

Percentage of scheduled time that the machine is operative.

Quality (Q)

Percentage of good parts versus total parts produced.

Performance (P): The Hidden Trap

This is where the error lies. Performance measures the speed of production against the “Ideal Cycle Time” (or Standard Time).

The problem: If your Ideal Cycle Time (Standard Time) is loose, estimated, or outdated, your OEE will be artificially high. You might see 95% OEE, but in reality, you are inefficient.

2. Why Methods Engineering is Critical for OEE

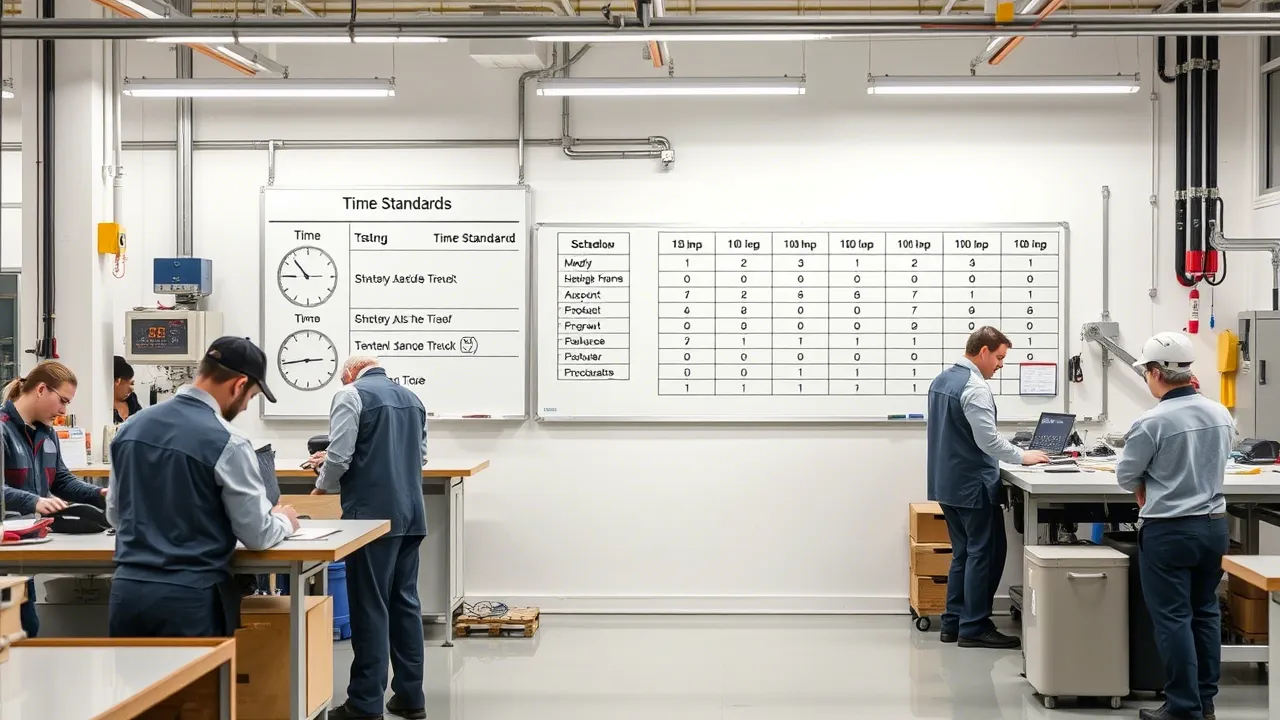

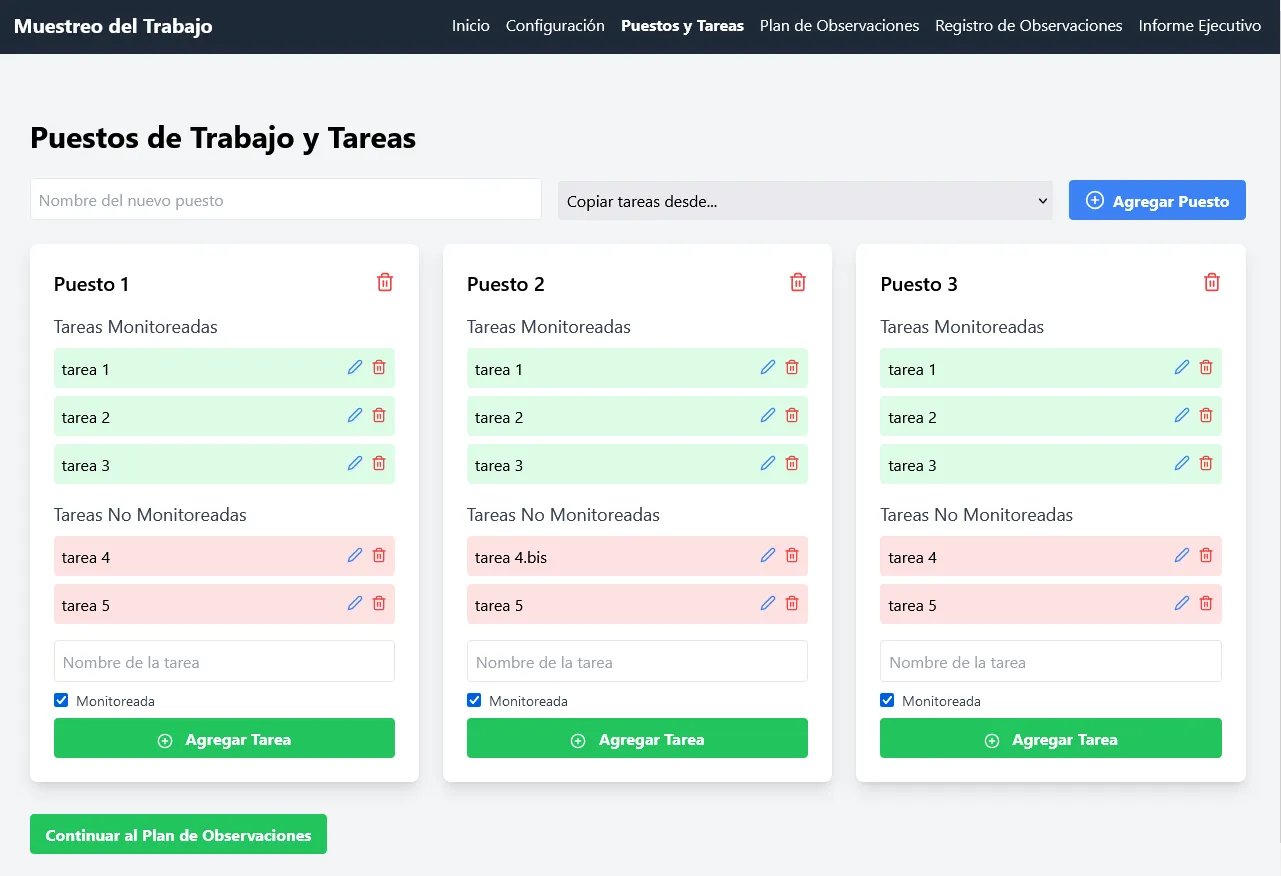

You cannot have a reliable OEE if your Standard Times are not scientifically measured.

- Stopwatch Estimation: Often includes “padding” or unrecognized idle times.

- Historical Averages: “We’ve always done 100 parts/hour.” This crystallizes past inefficiencies.

The Solution: Use MTM or rigorous time studies to set a true “100%” standard. Only then will your OEE reflect reality.

3. Impact on Costing

An incorrect OEE leads to incorrect product costing. If you think you are at maximum capacity (high OEE) but aren’t, you might buy new machines instead of optimizing the existing ones—a massive waste of CAPEX.

Conclusion

Don’t lie to yourself with vanity metrics. Update your master data with precise standard times to unlock the true potential of your OEE.

Calibrate your OEE with us. We verify your standard times to ensure your KPIs reflect reality.