When the work we are going to measure has a pre-established step-by-step process, then we record the work method to be timed.

Define the Type of Element

For this we will record:

-

The description of the task.

-

If it is an element: a. Machine Stopped (MS): The task is performed with the machine stopped or there is no machine involved in the process. It is work not restricted by machine time. b. Machine Running (MR): The task is performed during the time when the machine is performing its automatic operation. c. Machine Time (MT): The automatic machining time of the task.

-

The frequency or number of pieces resulting from each cycle.

-

If it is an element: a. Repetitive. This element repeats in each cycle of the task. b. Frequency. This element appears once every x cycles. c. Machine. It is a machine element.

Define the Frequency

Next to the text box where we generate the description of the element, we have a box where we will put the frequency or units processed in each cycle for that element. When assigning the frequency to a specific element, I must answer the question: each time this operation is performed, how many pieces are processed?

For example, if the operation is “sew a sleeve”, the frequency would be 1, whereas if the task consists of “bringing a box of scraps”, which I need to sew the sleeves and in that box of scraps there are 50 units, then this will be a frequency element and the frequency will be 50.

Editing an Element

When we have our method created, we can edit any element by clicking on it.

Deleting an Element

If we want to delete an element, we must swipe with our finger from the left side of the element to be deleted.

Once we have completed our work method by registering in it all the elements that make up our work standard, we press the arrow located in the upper right part of our screen or the back button on our phone or tablet to access the initial screen.

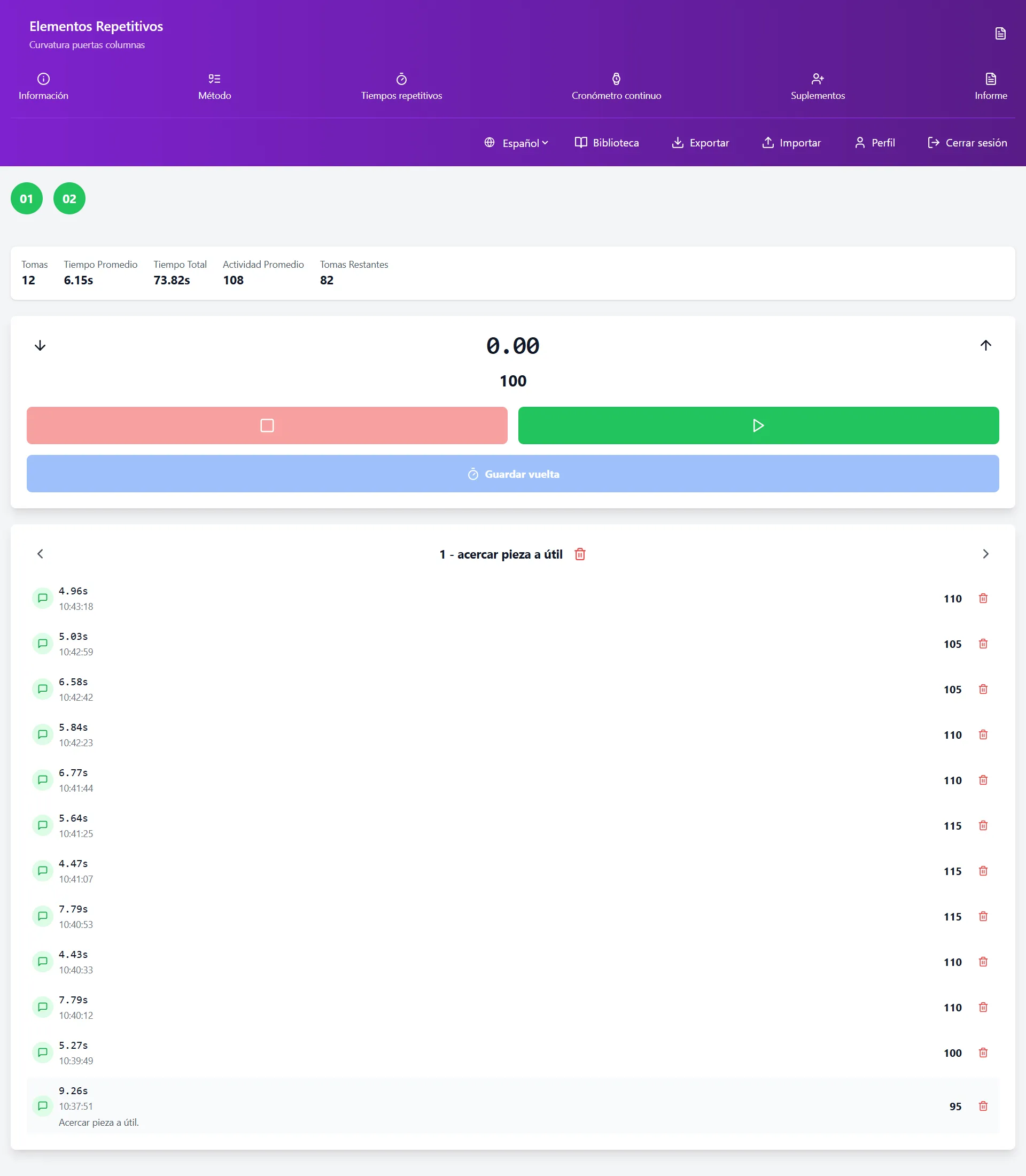

When accessing our initial screen again, we will see that there is now a new button called stopwatch. By pressing this button, we will access the screen where we can time our main cycle, that is, the repetitive elements that make up our work cycle.

Home screen with selected time study and created work method

Conclusion

Mastering industrial time study techniques is essential for any professional seeking to optimize production processes. The systematic application of these methods not only improves operational efficiency but also significantly contributes to cost reduction and increased business competitiveness. Remember that precision in measurement and rigorous data analysis are the basis for establishing reliable time standards that drive continuous improvement in your organization.