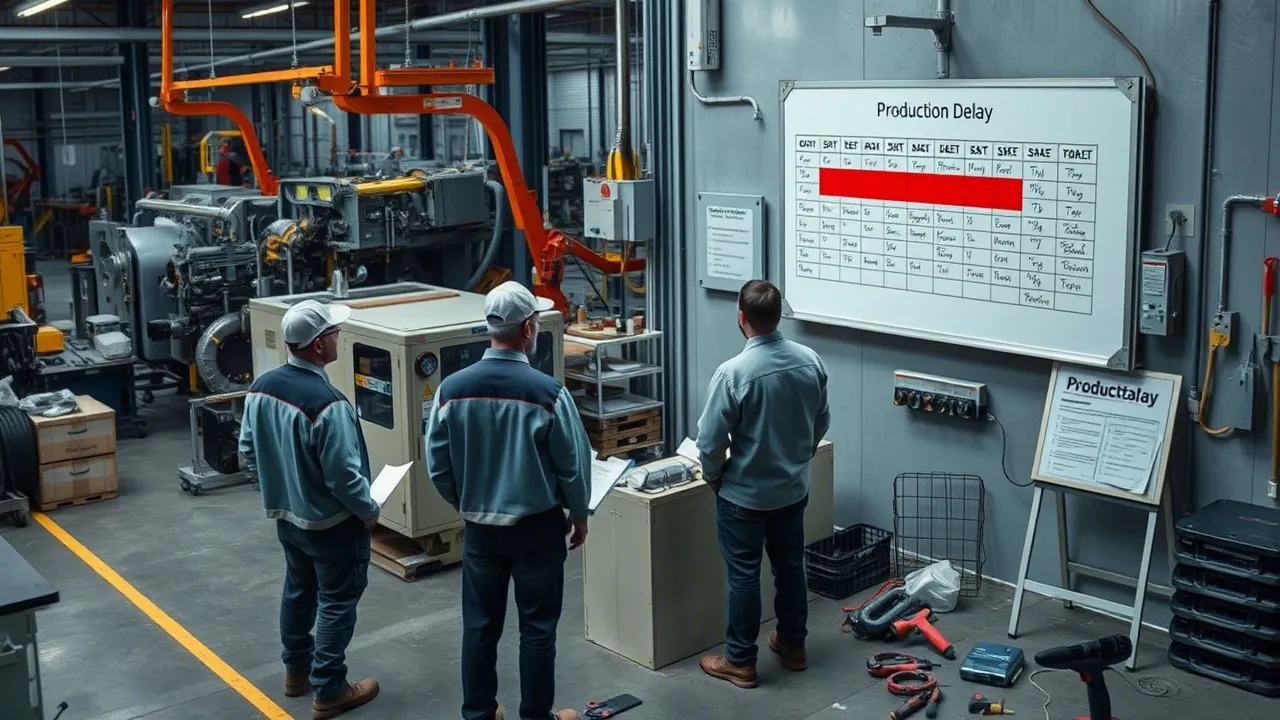

Production delays are a reality faced by many organizations. This is due to a variety of factors, from technical problems to poor business decisions. These delays can have a significant effect on a company’s production objectives, as they make it difficult to meet agreed deadlines. Therefore, it is important for all companies to understand the reasons behind production delays in order to take the necessary measures to avoid them.

Lack of resources

One of the main reasons why there are delays in production is the lack of adequate resources. This may be due to an inadequate selection of materials, equipment, personnel, or facilities to perform a job. If the available resources are not adequate for production, delays are inevitable.

Planning errors

Another common factor behind production delays is the lack of adequate planning. This may be due to a poor estimation of the necessary resources, a poor design of the production line, or poor control of deadlines. If the company does not adequately plan production, delays are likely to occur.

To help companies and professionals, there are tools such as the industrial time study app CronometrasApp, which will facilitate the task for planners by giving them a clear vision of the production times needed for a specific order.

Quality problems

There are also delays in production due to quality problems. These will inevitably stop or slow down production until they can be resolved and production can be launched again at normal speed.

Poor decisions

Production delays can also be due to poor business decisions. For example, if wrong decisions are made about product prices, delivery times, or materials to be used, this can cause delays in production.

It is important for companies to understand these reasons behind production delays in order to take the necessary measures to avoid them. This includes proper planning, the use of adequate resources, and quality control. These measures will help ensure that production is carried out without delay and that agreed deadlines are met.