Reducing lead time is an objective and result of any project or initiative to improve productivity, competitiveness, or efficiency. We help our clients in these three aspects, and therefore, reducing lead time is often one of the fundamental objectives of many of our projects.

What is lead time?

In an industrial environment, lead time is the time that elapses from when a part enters the factory as raw material or component until it leaves as part of the final product. Therefore, any reduction in this time and possible waste in its management will mean an improvement in the company’s productivity and the efficiency of its manufacturing processes.

It is important to note that lead time is a concept that not only applies in the industrial world, but in addition to manufacturing lead time, there is also logistics lead time (referring to the time of management, preparation, and delivery of an order) or GAP lead time, or waiting time deficit (which refers to the maximum time that customers accept to wait).

How to reduce lead time?

It is clear, then, that in a productive environment where efficient manufacturing is applied, reducing lead time is usually one of the fundamental objectives. It is about simultaneously reducing the lead time, not only of the process in question but also of the different subprocesses that are part of that process.

An optimal organization of stations and workstations, as well as processes and work methods, will allow achieving a reduction in lead time. In this way, with the same number of resources (workers, machines, etc.), it will be possible to produce more output in less time and, therefore, also at a lower cost.

Benefits of reducing lead time

As we have mentioned, an improvement in lead time mainly translates into increases in capacity, productivity, and competitiveness of the company, as well as reductions in inventory.

In addition to these benefits, there are also others derived from lead time reduction processes:

-

Greater flexibility when there are sudden changes in orders.

-

Greater ability to outperform competitors with faster and more efficient delivery.

-

Faster inventory replenishment, which allows avoiding excess stock and extra logistics or storage costs.

-

Meeting delivery deadlines and greater customer satisfaction.

-

Increased cash flow due to increased order fulfillment.

How is lead time calculated in a company?

To calculate lead time, it is necessary to take into account the factors that affect each company. However, there is a basic formula that can be useful as a guide:

Lead time = processing time + transportation time + setup time

-

Processing time is the time it takes to complete a process or task.

-

Transportation time is the time it takes to take a product or component from one place to another.

-

And setup time is the time it takes to prepare a product for delivery, such as packaging or labeling it.

Some of the ways in which these three times can be reduced are:

-

Improvement of the efficiency and effectiveness of production processes.

-

Automation of tasks and processes.

-

Optimization of logistics and transportation.

-

Improvement of the organization and planning of preparation processes for delivery.

In addition to the previously mentioned ways to reduce lead time, there are also some other strategies that can be effective:

-

Collaboration with suppliers: working closely with suppliers can help reduce lead time, as it can allow better planning and greater efficiency in the supply process.

-

Improvement of communication: good communication with customers and suppliers can help identify and solve lead time problems quickly.

-

Inventory management: proper inventory management can help reduce lead time by ensuring that the necessary parts are available at the right time.

-

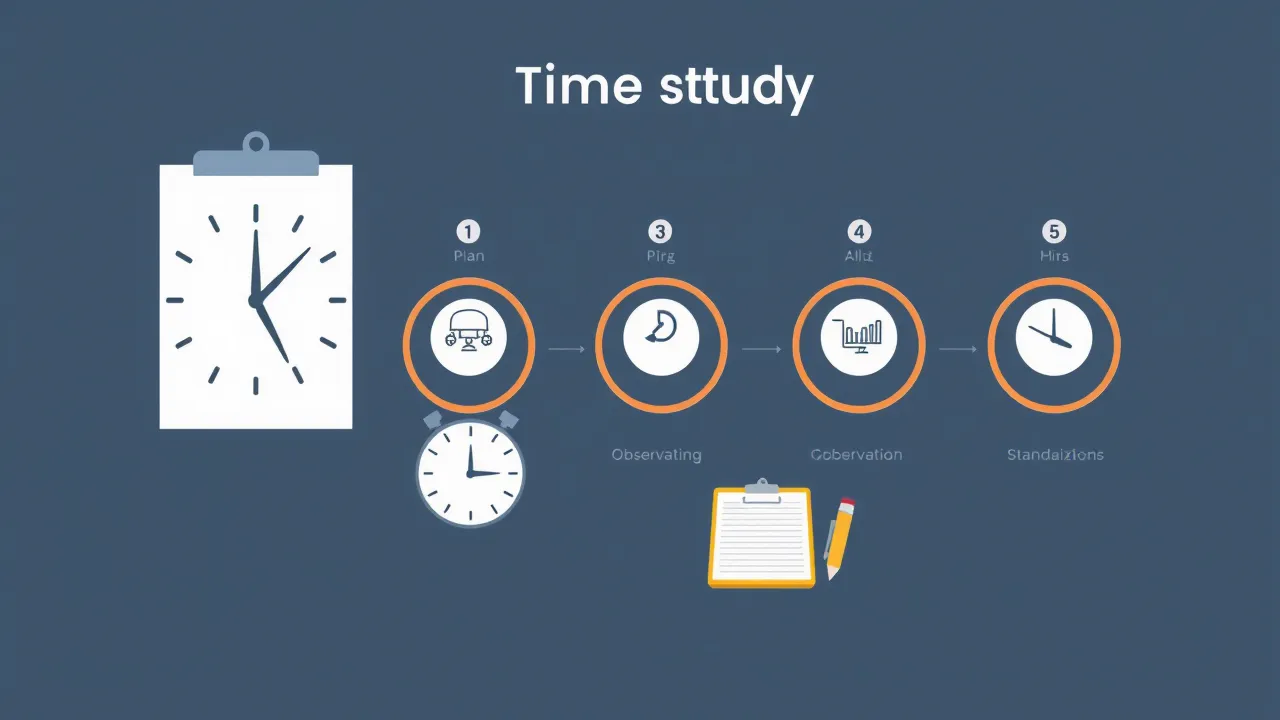

Continuous evaluation: it is important to regularly evaluate lead time and look for ways to improve it. This may include conducting time and motion analysis, implementing performance indicators, and conducting improvement tests. For this, it is important to have software designed for these tasks such as CronometrasApp

How to calculate lead time

To calculate lead time, it is necessary to take into account the factors that affect each company. However, there is a basic formula that can be useful as a guide:

Lead time = processing time + setup time + transportation time

-

Processing time is the time it takes to complete a process or task.

-

Transportation time is the time it takes to take a product or component from one place to another.

-

And setup time is the time it takes to prepare a product for delivery, such as packaging or labeling it.

To calculate these three times, it is necessary to keep a record of the times taken for each of them and then add them up. It can also be useful to keep a record of the lead time for each order or production batch, to be able to compare and evaluate performance over time.

It is important to note that lead time can vary depending on the type of product or service offered and according to the conditions of the production and delivery process. Therefore, it is important to regularly evaluate and monitor lead time and look for ways to improve it.

In summary, reducing lead time is an important objective to improve the productivity, competitiveness, and efficiency of a company. There are various ways to calculate and reduce lead time, and this can have significant benefits for the company and its customers.