Industrial Timekeeping 4.0: How to Use CronometrasApp to Ensure Statistical Precision and Regulatory Compliance (ISO/ILO)

Introduction: The End of “Estimation” and the Era of “Mathematical Precision”

Method engineering is at a critical turning point. With the imminent transition towards stricter regulatory frameworks in 2025 and the digitization of the plant floor, the use of physical centesimal stopwatches and field clipboards has become an unsustainable technical liability.

The digitization of timekeeping is not a matter of ergonomics or comfort; it is a requirement for statistical rigor. Recent studies show that manual data entry generates a transcription error of 4.2%.

The “Analog Gap” Problem: Sampling Errors in the Traditional Method

- Deviation Analysis: The manual process degrades data integrity. Deviations in the final calculation of Standard Time (St) range between ±7.5% due to human errors.

- The Fixed Sample Myth: Taking “10 cycles” by default is mathematically invalid if the Standard Deviation is not analyzed.

- Impact on Costs: Imprecision inflates Direct Labor Costs (DLC) by paying for performance that does not correspond to reality.

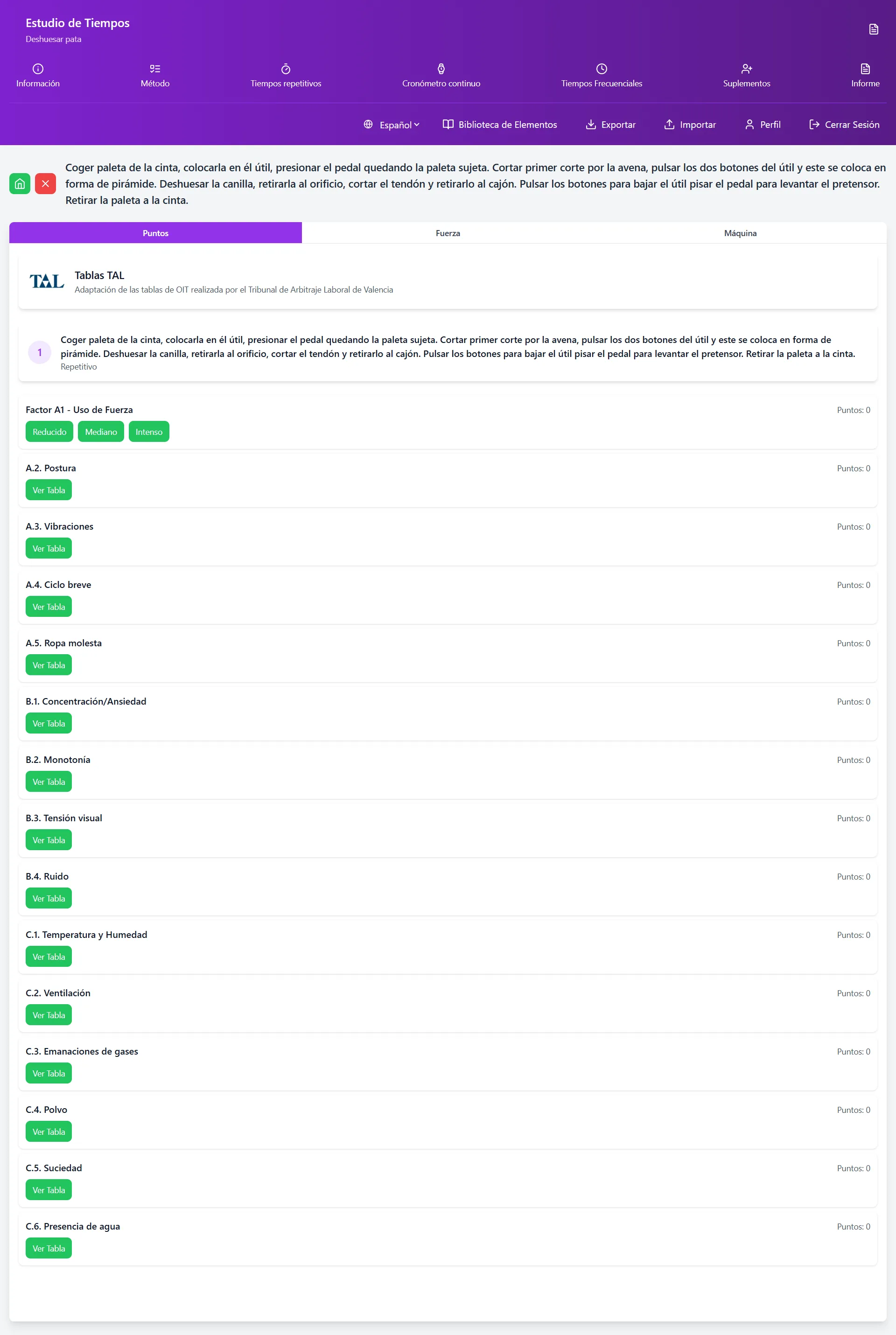

Data Architecture in CronometrasApp: Engineering Configuration

- Task Breakdown: Differentiation between regular and frequency elements (automatic prorating).

- Foreign Element Management: Segregation of incidents (breakages, waiting times) for Muda (Waste) analysis.

- Rating Systems: Supports Centesimal, Bedaux, or British Standard scales.

Timekeeping Execution: Real-Time Algorithms

- Fundamental Equation: Instantaneous calculation of Normal Time (Nt = Ot × Rating / Ref).

- Dynamic Sample Calculation: The software evaluates the Coefficient of Variation in real-time and alerts if more observations are needed to ensure a 95% Confidence Level.

- Outlier Filtering: Automated application of the Chauvenet Criterion to eliminate outliers.

2025 Regulatory Compliance and Legal Traceability

- Audit and Transparency: Compliance with Art. 64 of the Workers’ Statute through unalterable records with timestamps.

- Allowance Justification: Integration of fatigue matrices based on ILO/ILO tables (physical, mental load, etc.).

ROI and Technical Conclusion

| KPI | Manual Timekeeping | CronometrasApp | Technical Impact |

|---|---|---|---|

| Data Entry Time | 45 min / study | 0 min | 100% Saving |

| St Precision | ±7.5% (Error) | ±0.5% (Precision) | Robust Standards |

| Traceability | Null (Excel) | Total (Logs) | Legal Security |

Verdict: CronometrasApp allows engineers to stop being “time administrators” and become real productivity analysts in Industry 4.0.

Request a free demo to discover how CronometrasApp can transform your plant floor productivity.